What are you looking for?

Anti-Static PVC

| Transparency/clarity |

| Thermal insulation |

| Noise insulation |

| Long durability |

| Impact & scratch resistance |

| Environment friendly & recyclable |

Formats

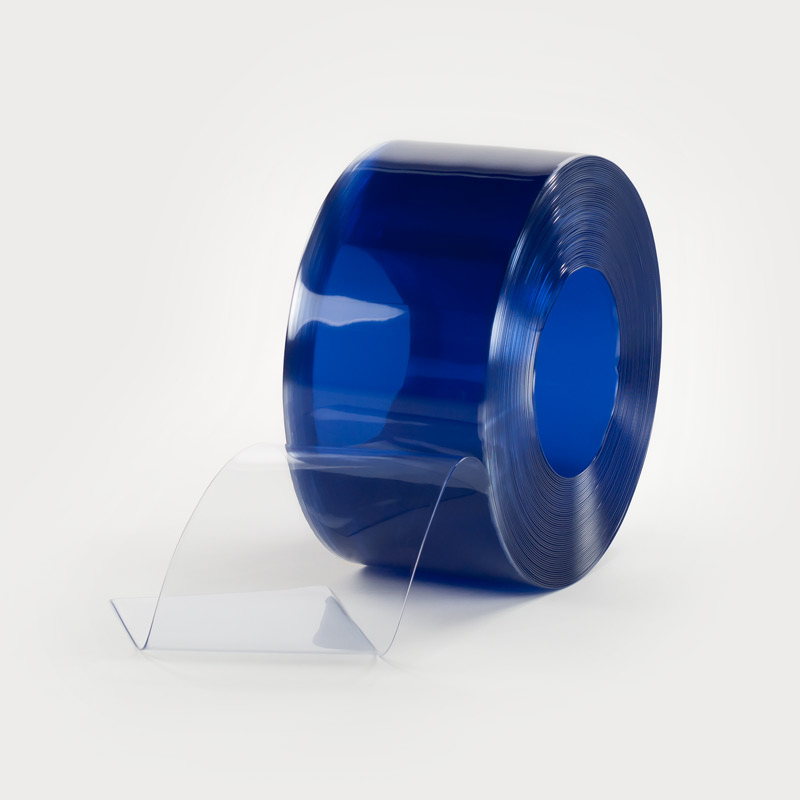

- Rolls, strips, curtains, panels and films

- Smooth, ribbed, reinforced, rounded edges, matt surface

| Min | Max | |

| Width | 75 mm | 2.2 m |

| Thickness | 1 mm | 12 mm |

| Length | 20 m | 100 m |

About Anti-Static PVC

Anti-Static PVC is a high static dissipative (antistatic) material. It avoids sparks and all others damage resulting of static electrical charges.

Anti-Static strip doors and partitions can be used in varied applications such as explosive atmosphere (mining, chemical sites, laboratories, etc…) or in static electric sensitive areas (data-centers, cleanrooms, electronic parts factories, packaging, etc…)

Applications

Why Use Anti-Static PVC?

Extruflex Anti-Static PVC reduces the risk of sparks caused by static electricity.

Anti-Static PVC is an advanced, high-static-dissipative material, meticulously designed to mitigate the risks associated with static electrical charges.

Extruflex Anti-Static PVC is specifically engineered for application within electrostatic environments, with a primary focus on its widespread adoption in data centres and server rooms. This specialised PVC material effectively dissipate static charges generated by machinery in the area, simultaneously leveraging its thermal properties to regulate temperature and safeguard critical equipment contaminants such as dust or pests.

Excels In Dissipating Static Charges

Dissipative materials allow charges to flow to the ground slowly and safely, preventing sudden discharges.

They have moderate electrical resistance, which is sufficient to dissipate charges without causing sparks.

Extruflex Anti-Static PVC contains additives that increase their conductivity without making them fully conductive.

Common Applications

- Data centres

- Server rooms

- Cleanrooms

- Manufacturing

- Engineering factories

- Electronic telecom facilities

- Computer technology industry

Protects Sensitive Equipment

This material effectively dissipates static charges, thereby reducing the risk of sparks that could potentially lead to fire incidents or the damage of sensitive equipment.

Furthermore, it contributes to temperature regulation within the working environment, by acting as an insulator, aiding in temperature control systems and thereby ensuring the optimal functioning of crucial machinery by maintaining a controlled and cool temperature.

Helps Prevent Fires

Anti-Static PVC is strategically to proactively address the initial stages of fire prevention. By effectively managing and dissipating static electricity, it functions as a preventive measure to avert fire hazards stemming from electrostatic discharge.

This is especially important in industries where even the smallest spark can create a fire hazard, such as in fuel production, mining, chemical labs, etc.

Special Data Centres

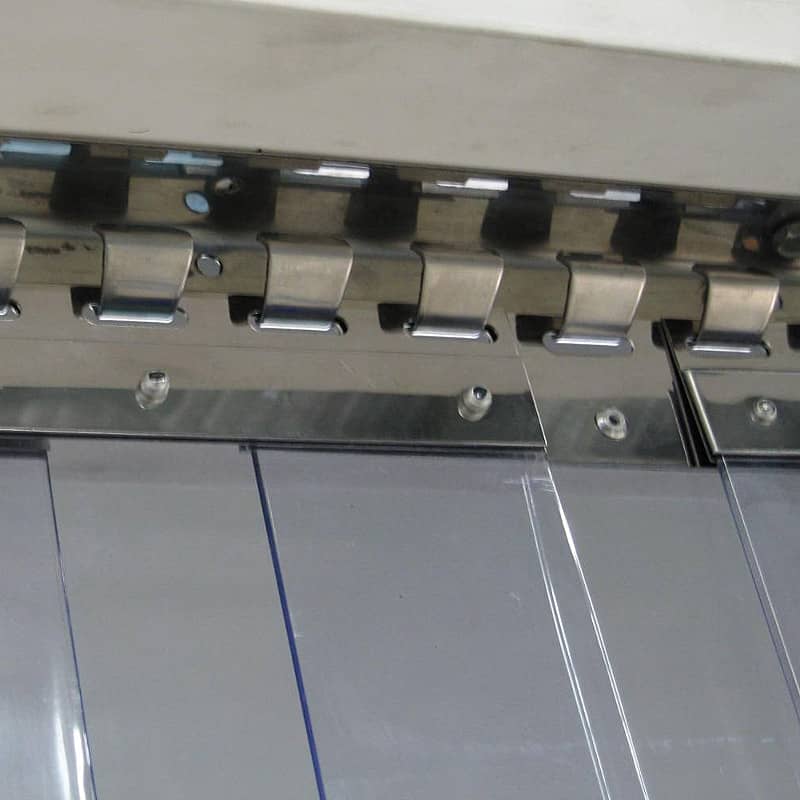

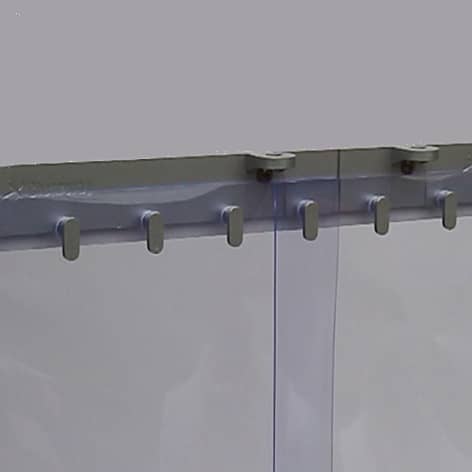

Anti-Static PVC strips are commonly used in data centers to contain cold and hot aisles,manage airflow, enhance energy efficiency, and maintain a controlled environment.

They prevent the mixing of hot and cold air, thereby optimizing cooling system performance and reducing energy costs.

Additionally, these strips help control dust and humidity, are easy to install and remove, and provide easy access to equipment while being durable and resistant to fire and chemicals.

Due to their cost-effectiveness and efficiency, PVC strips are a valuable solution for thermal management in data centers.

Technical datasheet

| Properties | Standard | Units | Standard | Description |

| Light transmittance | ASTM D 1003 | % | 85 | Visible light rate transmitted through the material. |

| Shore A hardness | EN ISO 868 | Sh A | 80 | Index based on a flat indenter's penetration depth. Scale from 0 (Soft) to 100 (Hard). |

| Tearing resistance | DIN 53515 | N/mm | 50 | Minimum tensile stress required to tear a pre-slit sample. |

| Tensile strength at break | ASTM D 638 EN ISO 527 | N/mm² | 16 | Maximum tensile stress that a material can be subjected to before break. |

| Elongation at break | % | 340 | Elongation of the specimen at the break point under tensile stress. | |

| Residual elong. (after break) | % | 68 | Permanent elongation of the specimen measured after rupture in a tensile test. | |

| Thermal conductivity | ASTM C 177 | W/m.K | 0,16 | Ability to conduct heat. The lower it is, the more insulation. |

| Cold bend brittle temp. | ISO 8570 | °C | -35 | Temperature at which the specimen break under torsion stress. Brittle point (CLASH & BERG). |

| Min. usage temp. | EN 1876 | °C | -15 | Temperature range where material keeps its mechanical properties (flexibility). |

| Max. usage temp. | °C | +50 | ||

| Specific heat capacity | ISO 11357 | kJ/kg.K | 1,6 | Heat energy required to increase the temperature of one kilogram of the material by one degree Celsius. |

| Sound reduction | DIN 52210 | dB | >35 | Average sound level (freq. 0,1 to 3,2 kHz) decreased by a 1,76 sq.m. and 5 mm thick PVC curtain. |

| Reaction to fire | EN 13501-1 | Class | - | Standard classifications of material self-extinguishing and resistance to combustion. |

| UV/IR filter | ISO 25980 | - | - | Ability to filter welding rays allowing the use of this material as a welding protection screen. |

| UV resistance | ISO4892 | - | Yes | Ability to resist to UV (Sun, welding arc). |

| Surface resistivity | ASTM D257 | .1010 Ω/□ | 3 | Material surface electric resistivity measured with a 100 V direct voltage. |

| Water absorption | EN ISO 62 | % | 1 to 1,6 | Material mass variation after exposure to humid conditions. (<0 if released / >0 if absorbed) |

| Anti-insect | - | - | - | Special ability to keep insects away.(Food processing plants, tropical regions) |

| Density | ASTM D 792 | g/cm3 | 1,22 | Mass per unit volume. |

Free download

- FLEXIBLE VINYL - NON-PHTHALATE PLASTICIZER (EN).pdf

- FLEXIBLE VINYL - SOLUTION FOR BUILDING (EN).pdf

- FLEXIBLE VINYL - SOUND REDUCTION (EN).pdf

- FLEXIBLE VINYL - THICKNESS & THERMAL INSULATION (EN).pdf

- FLEXIBLE VINYL - THERMAL INSULATION (EN).pdf

- FLEXIBLE VINYL - STABILIZERS & DURABILITY (EN).pdf

- PLASTIC MATERIALS & EARTH’S ENERGY RESOURCES (EN).pdf

- PLASTIC MATERIALS & GLOBAL WARMING (EN).pdf

- PLASTIC MATERIALS & OIL RESSOURCES (EN).pdf