Carbon footprint, our commitments

Since the beginning of this year, our products have prevented the emission of :

Flexible vinyl has many intrinsic advantages in terms of carbon footprint: low processing temperature, composition including salt, possibility of using recycled or biobased materials, insulating properties.

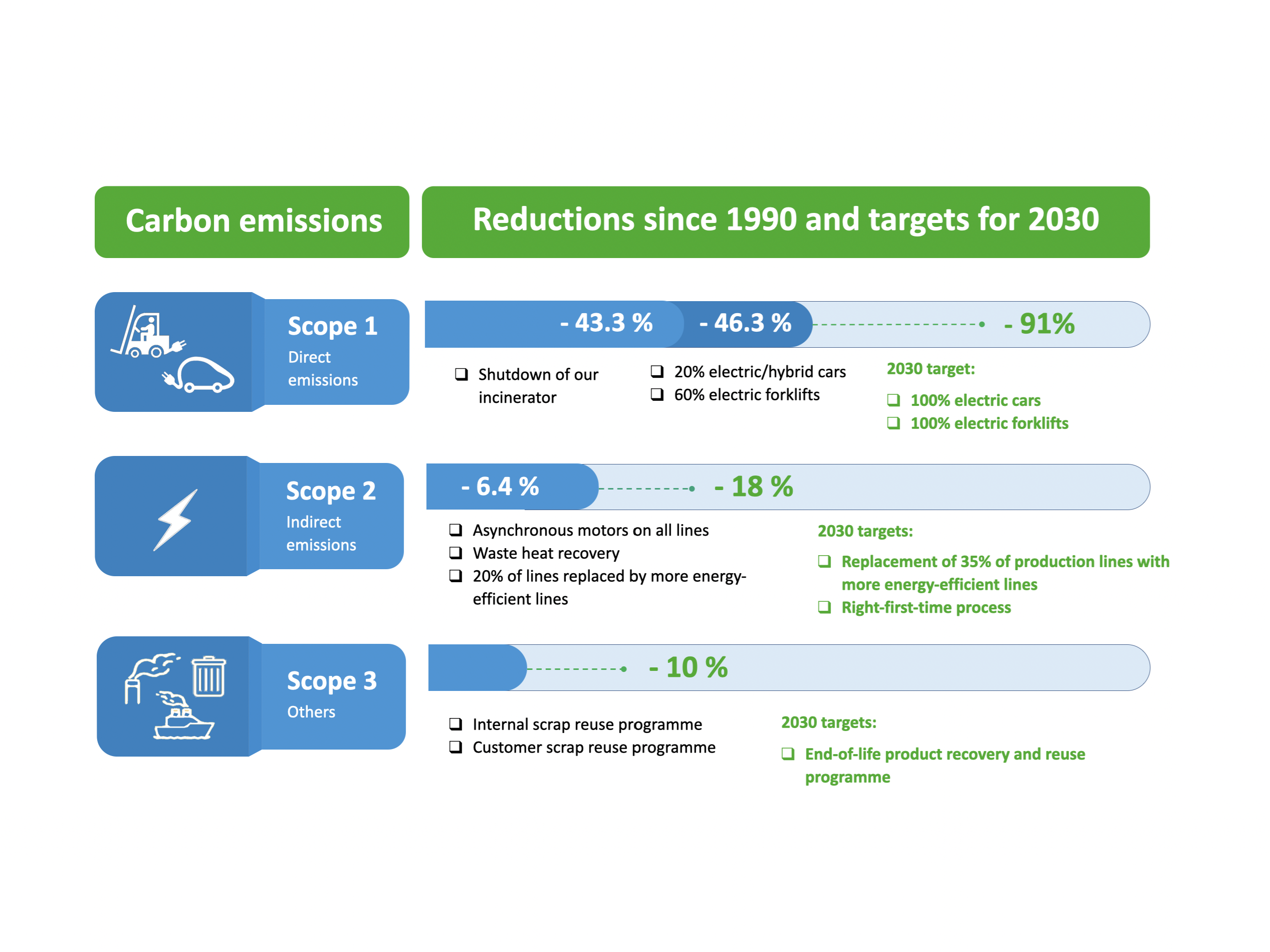

In addition to these advantages of flexible vinyl, Extruflex has carried out a carbon audit of its activities and taken steps to reduce its CO2 emissions.

Our goals for 2030

Flexible vinyl is an excellent thermal insulator, and its use as a partition or flexible door with strips or leaves keeps out the cold in winter and the heat in summer. This simple, effective and energy-efficient solution greatly reduces heat loss and heating in cold rooms and workshops.

A flexible vinyl door or partition can significantly reduce your heating and air-conditioning consumption. It contributes to reducing carbon emissions more than it emits itself throughout its life cycle.

Towards even less carbon

Actions on Scope 1 |

Actions on Scope 2 |

Actions on Scope 3 |

Energy savings for our customers |

|

|

|

|

Reduction of CO₂ emissions |

Reduction of CO₂ emissions |

Reduction of CO₂ emissions |

Reduction of CO₂ emissions |