What are you looking for?

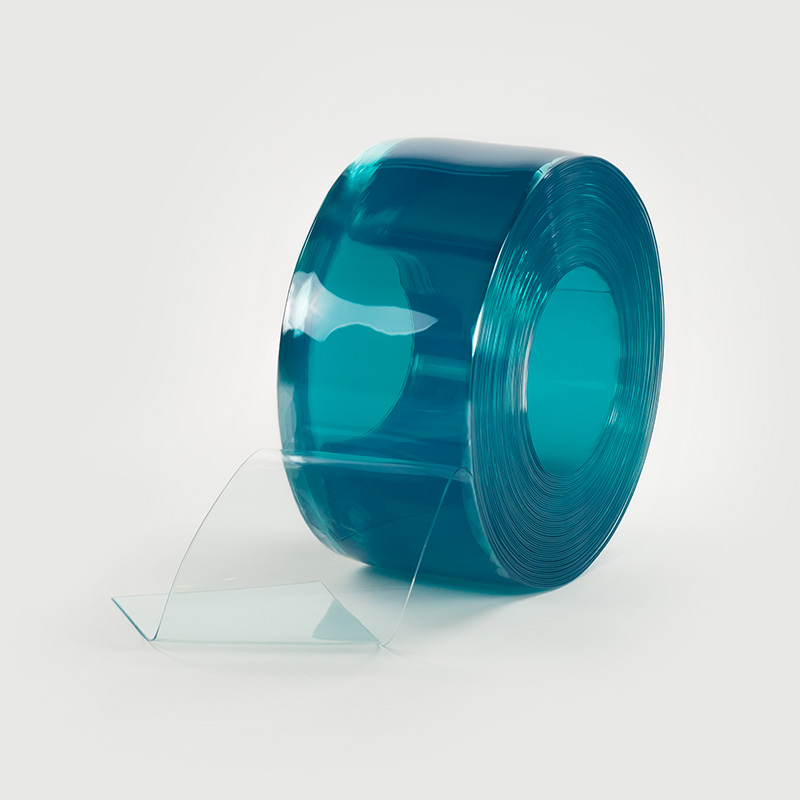

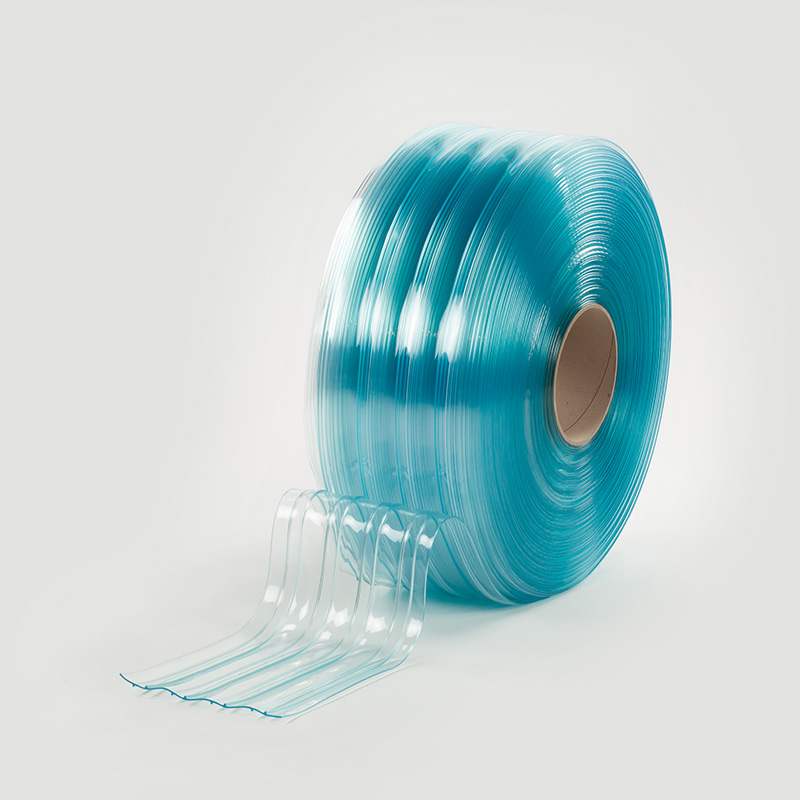

Super Polar PVC

| High thermal insulation |

| High flexibility at low temperature |

| Strong mechanical resistance down to -25°C |

| Energy and cost savings |

| Very high clarity/transparency |

| Environment friendly & recyclable |

Formats

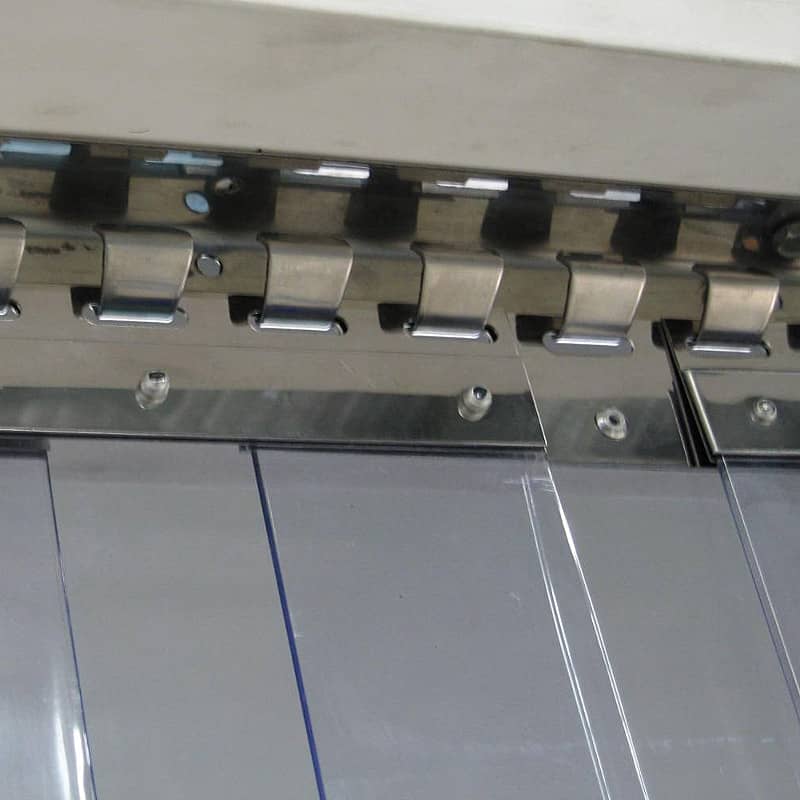

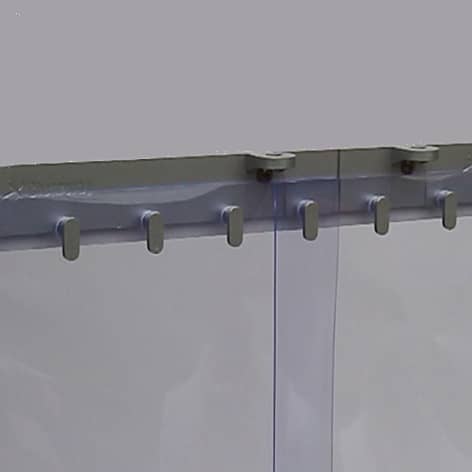

- Rolls, strips, curtains, panels and films

- Ribbed, reinforced with nylon and rounded edges

| Min | Max | |

| Width | 75 mm | 2.2 m |

| Thickness | 0.3 mm | 12 mm |

| Length | 20 m | 100 m |

Super Polar PVC

Extruflex's Super Polar is commonly used in very low temperature environments because of a very high insulating power: it will reduce temperature loss, increase energy savings, and reduce costs.

Strips and panel stay flexible, resist breaking and cracking whether it be an inside or outside application where temperatures vary from -60°C to +15°C.

Super Polar PVC is recommended for extremely cold blast freezers.

Applications

Why Choose Super Polar PVC for Your Project?

In these applications, maintaining the desired temperature requires specialized equipment such as refrigeration systems, environmental chambers, or cryogenic coolants, along with proper insulation and temperature control mechanisms.

Additionally, safety considerations are crucial to ensure personnel and environmental safety when working with extremely cold temperatures.

Common applications

Cold Storage: Many perishable goods, such as certain foods and pharmaceuticals, require storage at temperatures below freezing to prolong shelf life.

Climate Testing: Testing the performance of materials, components, and systems under extreme cold conditions, such as automotive parts, aerospace components, and electronics. Very low temperature simulations can help assess durability and reliability in harsh environments.

Laboratory Research: Certain laboratory experiments and processes require controlled low temperatures. This could include biochemical reactions, material science studies, and testing of equipment performance under cold conditions.

Cold Weather Testing: Testing equipment, clothing, and vehicles for use in cold climates or extreme outdoor conditions. These temperature are closer to the temperatures encountered in polar regions or high-altitude environments.

Environmental Chambers: Certain industrial processes, such as polymer processing or testing of materials, may require controlled temperatures, including sub-zero temperatures like -65°C, within environmental chambers to simulate real-world conditions.

Refrigeration: Some industrial processes or facilities may require refrigeration at that temperature for specific manufacturing or storage needs, such as in the food industry for certain frozen foods or in pharmaceutical production for certain medications.

Technical datasheet

| Properties | Standard | Units | Standard | Description |

| Light transmittance | ASTM D 1003 | % | 85 | Visible light rate transmitted through the material. |

| Shore A hardness | EN ISO 868 | Sh A | 62 | Index based on a flat indenter's penetration depth. Scale from 0 (Soft) to 100 (Hard). |

| Tearing resistance | DIN 53515 | N/mm | 25 | Minimum tensile stress required to tear a pre-slit sample. |

| Tensile strength at break | ASTM D 638 EN ISO 527 | N/mm² | 10 | Maximum tensile stress that a material can be subjected to before break. |

| Elongation at break | % | 420 | Elongation of the specimen at the break point under tensile stress. | |

| Residual elong. (after break) | % | 80 | Permanent elongation of the specimen measured after rupture in a tensile test. | |

| Thermal conductivity | ASTM C 177 | W/m.K | 0,16 | Ability to conduct heat. The lower it is, the more insulation. |

| Cold bend brittle temp. | ISO 8570 | °C | -65 | Temperature at which the specimen break under torsion stress. Brittle point (CLASH & BERG). |

| Min. usage temp. | EN 1876 | °C | -60 | Temperature range where material keep its mechanical properties (flexibility). |

| Max. usage temp. | °C | +15 | ||

| Specific heat capacity | ISO 11357 | kJ/kg.K | 1,6 | Heat energy required to increase the temperature of one kilogram of the material by one degree Celsius. |

| Sound reduction | DIN 52210 | dB | >35 | Average sound level (freq. 0,1 to 3,2 kHz) decreased by a 1,76 sq.m. and 5 mm thick PVC curtain. |

| Reaction to fire | EN 13501-1 | Class | - | Standard classifications of material self-extinguishing and resistance to combustion. |

| UV/IR filter | ISO 25980 | - | - | Ability to filter welding rays allowing the use of this material as a welding protection screen. |

| UV resistance | ISO4892 | - | Yes | Ability to resist to UV (Sun, welding arc). |

| Surface resistivity | ASTM D257 | .1010 Ω/□ | 3 | Material surface electric resistivity measured with a 100 V direct voltage. |

| Water absorption | EN ISO 62 | % | -0,2 | Material mass variation after exposure to humid conditions. (<0 if released / >0 if absorbed) |

| Anti-insect | - | - | - | Special ability to keep insects away.(Food processing plants, tropical regions) |

| Density | ASTM D 792 | g/cm3 | 1,18 | Mass per unit volume. |

This information given to our customer in good faith to inform them and to help them in their search, does not constitute any formal or implicit guarantees as to its use.

Free download

- FLEXIBLE VINYL - NON-PHTHALATE PLASTICIZER (EN).pdf

- FLEXIBLE VINYL - SOLUTION FOR BUILDING (EN).pdf

- FLEXIBLE VINYL - SOUND REDUCTION (EN).pdf

- FLEXIBLE VINYL - THICKNESS & THERMAL INSULATION (EN).pdf

- FLEXIBLE VINYL - THERMAL INSULATION (EN).pdf

- FLEXIBLE VINYL - STABILIZERS & DURABILITY (EN).pdf

- PLASTIC MATERIALS & EARTH’S ENERGY RESOURCES (EN).pdf

- PLASTIC MATERIALS & GLOBAL WARMING (EN).pdf

- PLASTIC MATERIALS & OIL RESSOURCES (EN).pdf