What are you looking for?

FINEVINYL® Fire-Retardant

| Fire-retardant performance |

| Certified to international fire standards |

| Maintains transparency and flexibility |

| UV-stabilized formulation |

| Low shrinkage and stable performance |

| Excellent weldability |

Formats

- Rolls of 20, 25, 40, 50, 65 or 100m

- 16 rolls/pallet

| Min | Max | |

| Width | 200 mm | 1.4 m |

| Thickness | 0.3 mm | 1 mm |

| Length | 20 m | 100 m |

About FINEVINYL® Fire-Retardant

FINEVINYL® Fire-Retardant films are transparent PVC films engineered for applications where fire safety and regulatory compliance are required, without compromising clarity or usability. Designed for public, commercial, and industrial environments, these films combine optical transparency with mechanical durability and proven fire-retardant behavior.Finevinyl Fire-Retardant films are available in formulations tested to international fire safety standards and are suitable for both indoor and light-exposed environments. They allow light to pass through while helping reduce ignition risk and limit flame spread when exposed to fire sources.

Finevinyl Fire-Retardant films are available in formulations tested and certified to meet international fire safety standards, including:

- M2 / B1 (NF P92-507)

- BS 7837

- NFPA 701

Certain formulations can also meet Euroclass B,s3-d0 requirements, depending on configuration and thickness.

Advantages

- Fire-retardant performance designed for regulated environments

- Helps reduce ignition risk and slow flame spread

- Maintains transparency and flexibility for practical daily use

- UV-stabilized formulations suitable for light-exposed applications

- Low shrinkage for stable fabrication and consistent fit

- Non-sticky surface for easier processing and cleaner finished results

- Excellent weldability for efficient fabrication and joining

- Available in multiple thicknesses and roll formats to match the application

产品用途

How Does Fire Retardant PVC Work ?

To stop a fire, simply remove or reduce one of the three components of the fire triangle:

- Heat Elimination

- Fuel Disposal

- Oxygen Elimination

In soft PVC, the fire retardants can promote the formation of a stable char layer on the surface of PVC.

This char layer acts as a thermal barrier, reducing heat transfer (HEAT) to the underlying material and slowing down the release of flammable volatiles(FUEL).

French M2 fire test

The M2 fire rating is a French classification that evaluates the reaction of materials to fire, indicating that they are difficult to ignite.

Part of a scale ranging from M0 (incombustible) to M4 (easily flammable), M2 materials do not catch fire easily and contribute minimally to the spread of flames.

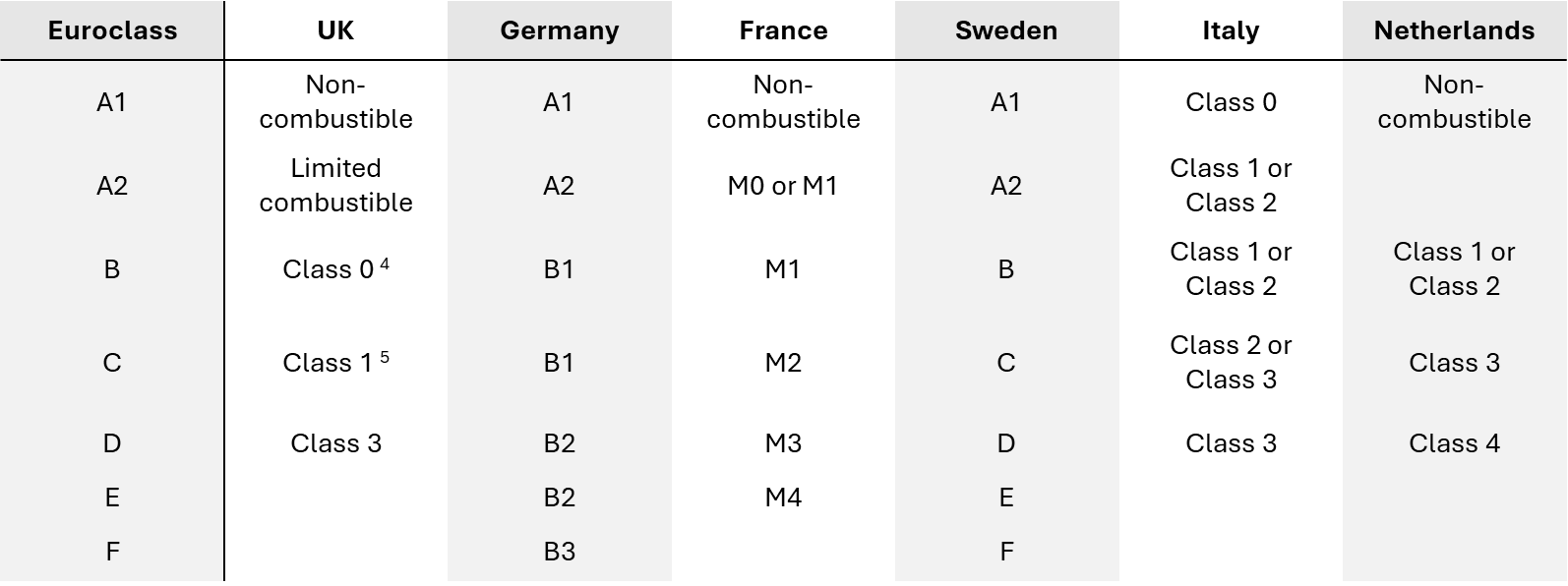

Euroclass System

Euroclass B materials show very low contribution to fire. Classification is determined through standardized tests such as the SBI (Single Burning Item) test and flame spread tests, with additional ratings for smoke production (s1–s3) and flaming droplets (d0–d2).

Equivalence Between European's Standard

Technical Datasheet

| PROPERTIES | TEST METHOD | UNIT | STANDARD (3S) | FIRE RETARDANT | STANDARD (2S) |

| REFERENCE | - | - | REF425 | REF690 | REF436 |

| WIDTH | - | mm | 1400 | 1400 | 1400 |

| LENGTH | - | m | 20 to 65* | 20 to 65* | 20 to 65* |

| HAND | - | - | 3S | 3S | 2S |

| WEIGHT / roll | - | kg | 35 | 36 | 35 |

| WEIGHT / m² | - | gr /m² | 372 to 1240* | 390 to 1300* | 375 to 1255* |

| WEIGHT / m | - | gr /m | 520 to 1736* | 546 to 1820* | 525 to 1760* |

| FINISH | - | - | DOUBLE POLISHED | DOUBLE POLISHED | DOUBLE POLISHED |

| COLOR | - | - | CLEAR BLUE | CLEAR BLUE | CLEAR BLUE |

| UV STABILIZED | - | - | YES | YES | YES |

| FIRE RETARDANT | NF P92-507 | - | - | M2/B1 | - |

| LOW TEMP RESISTANCE (IMPACT TEST) | ASTM D746 | °C | -40 to -30* | -7 to -25* | -25 to -35* |

| TEAR RESISTANCE | ASTM D1004-13 | N | 21 to 70 (X)* 19 to 66 (Y)* | 19 to 67 (X)* 17 to 65 (Y)* | 23 to 78 (X)* 21 to 72 (Y)* |

| TENSILE STRENGTH | ISO 527-1:2012 ISO 527-3:2001 | MPa | 20 to 26 (X)* 25 to 29 (Y)* | 18 to 23 (X)* 15 to 26 (Y)* | 22 to 28 (X)* 27 to 32 (Y)* |

| ELONGATION AT BREAK | ISO 527-1:2012 ISO 527-3:2001 | % | 350 to 380 (X)* 320 to 420 (Y)* | 340 to 370 (X)* 310 to 400 (Y)* | 330 to 360 (X)* 310 to 390 (Y)* |

| HEAT SHRINKAGE (80°C, 10 min.) | DIN 53377:2007 | % | 0.7 (X) -2.2 (Y) | 0.9 (X) -2.7 (Y) | 0.5 (X) -1.9 (Y) |

The data contained in this technical specification is given for information only and is based on our current knowledge of the products concerned.

This information given to our customer in good faith to inform him and to help him in his search, does not constitute any formal or implicit guarantees as to its use.

供免费下载的文件

- FINEVINYL - BROCHURE (EN).pdf

- FLEXIBLE VINYL - SOLUTION FOR BUILDING (EN).pdf

- FLEXIBLE VINYL - STABILIZERS & DURABILITY (EN).pdf

- PLASTIC MATERIALS & EARTH’S ENERGY RESOURCES (EN).pdf

- PLASTIC MATERIALS & GLOBAL WARMING (EN).pdf

- PLASTIC MATERIALS & OIL RESSOURCES (EN).pdf

- FLEXIBLE VINYL - THERMAL INSULATION (EN).pdf