What are you looking for?

可循环热熔模

| Cost effective |

| Detailed reproductions |

| Adjustable flexibility and resistance to deformation |

| Reusable (more than 50 times) |

| Ideal for small and large size mold (until few meters) |

Format

Vinamold® is available in 5 grades (Red, Natural, White, Blue, Yellow) for better reproduction, better resistance to deformation and durability.

Size : bags of 12,5 or 25kg

Red for high detailled reproductions

Yellow for large reproduction size

White for multiple re-uses

Blue, best compromize with all features

About Vinamold

Vinamold® is a hot melt compound which is meltable compositions used for the preparation of flexible molds. It is an economic alternative to silicone rubber, polyurethane and rubber latex for casting concrete, gypsum, polyester resins.

Vinamold® is an established name within the industry due to the unrivalled quality and versatility. For over 30 years clients know and trust the brand named which is a cost effective material for recreating article in a variety of various materials (i.e. plaster, reconstituted stone articles, polyester, glass fiber laminates…).

A Hot Melt PVC Compound, Meticulously Crafted for Creating Flexible Moulds

产品用途

Why Use Vinamold® ?

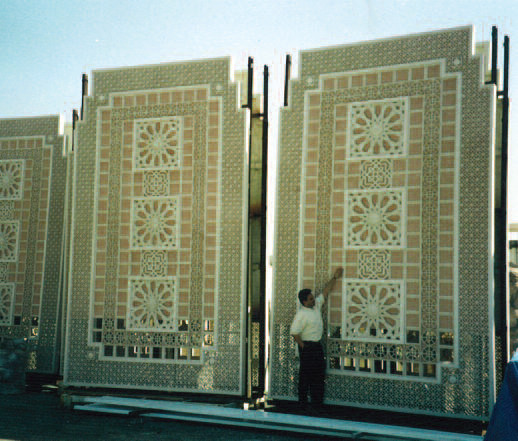

A hot melt compound based on vinyl resins for making flexible molds. Suitable for casting polyester, plaster, epoxy, and phenol-formaldehyde resins. Vinamold is flexible, melts at 150-170°C, and pours at 140-150°C. The molds are waterproof, chemical-resistant, and unaffected by climate. They capture fine details and allow multiple casts before being re-melted and reused.

Common Applications:

- Arts and crafts

- Interior decorating

- Casting detailed objects

- Ornamental designs

- Creating moulded replicas

- Three-dimensional models

Which Colour is Best for My Application?

- Red Vinamold: Softest materials, allowing for reproduction of very detailed parts and objects. Ideal for highly precise reproduction of arts & crafts parts with a high level of detail.

- White Vinamold: Combine flexibility with strength to reproduce small to medium-sized souvenirs with a good level of detail . Can be used multiple times before being replaced

- Blue Vinamold: Material with good general properties. Allowing medium to large-size interior decoration reproductions with a suitable level of detail.

- Yellow Vinamold: Hardest material specially designed for large size and/or heavy construction part reproduction.

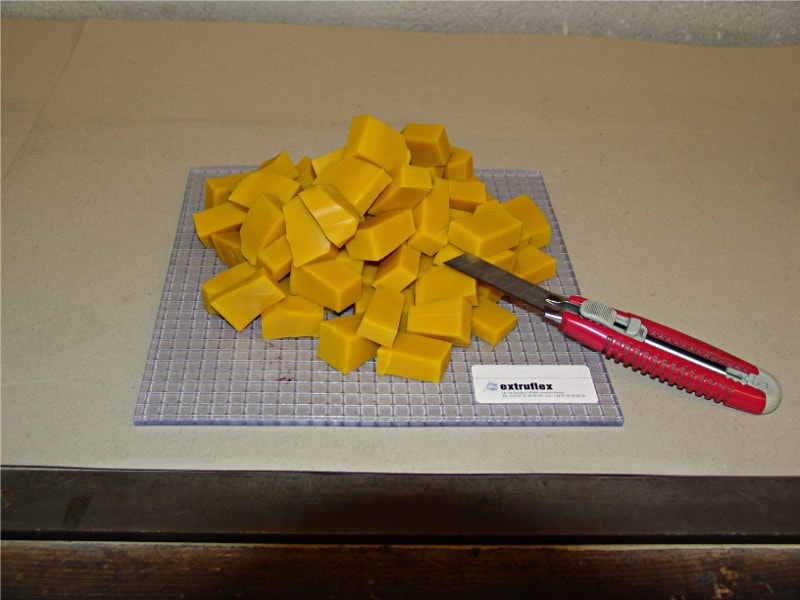

How to use Vinamold correctly

Melting process:

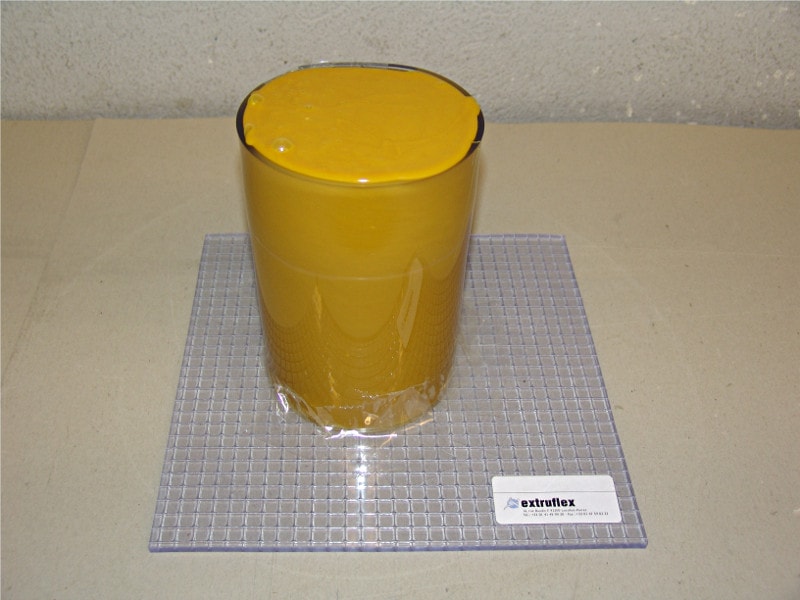

Vinamold can be melted using various methods including microwaves, but for best results, we recommend using thermostatically controlled melting equipment. This ensures the material melts consistently and correctly at a stable temperature. The material should reach a liquid state without any discoloration or smoke. If overheating occurs, as indicated by these signs, the material should be discarded.

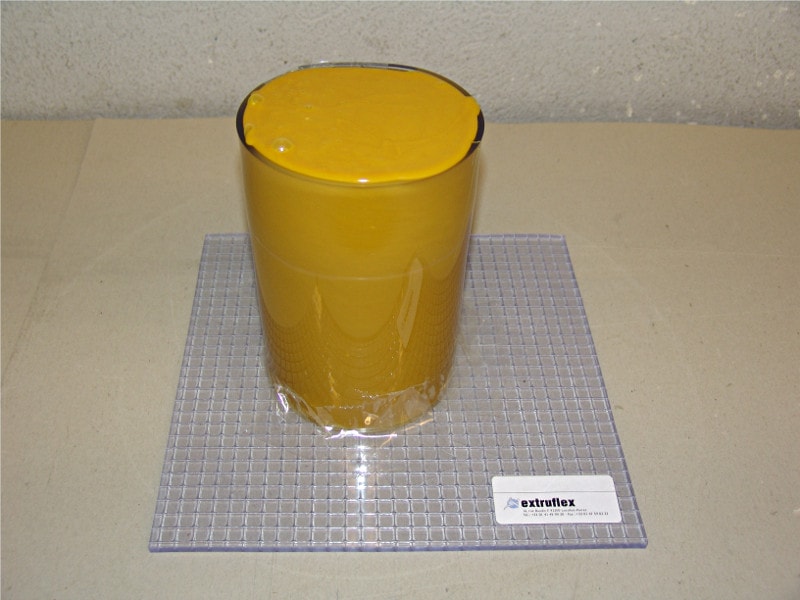

Pouring process:

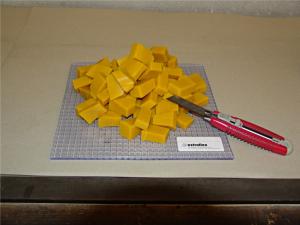

After melting Vinamold, pour the molten material slowly and steadily to the required depth, ensuring a minimum coverage of 20mm. To avoid trapping air, it may be necessary to maneuver the assembly, allowing the liquid to fill all details; having an assistant can be helpful. Allow the finished mold to set for at least 8 hours before attempting to release it. For intricate or smooth surfaces, this process may take longer and should involve gentle manipulation rather than tools that could cut or tear the PVC. Minor imperfections, such as air bubbles or tears, can be corrected by carefully touching up with a hot blade. If needed, small pieces of Vinamold can be fused into the mold surface to fill any cavities that may form if not properly addressed.

Safety first

When handling molten Vinamold, exercise extreme caution as it melts at temperatures above 150°C (302°F) and can cause burns. Avoid inhaling fumes during melting; although not toxic, the vapors from plasticizers can be irritating. Ensure adequate ventilation and extraction in the heating area to minimize discomfort and respiratory irritation.

Technical Datasheet

| Properties | Standard | Units | Red | Natural | White | Blue | Yellow | Description |

| Shore A hardness | ASTM D 2240 | Shore 00 | 40 | 40 | 47 | 55 | 70 | Index based on a flat indenter's penetration depth. Scale from 0 (Soft) to 100 (Hard). |

| Tensile strength at break | ISO 37 | Mpa | 0,29 | 0,29 | 0,60 | 0,50 | 0,65 | Maximum tensile stress that a material can be subjected to before break. |

| Elongation at break | % | 178 | 178 | 293 | 182 | 176 | Elongation of the specimen at the break point under tensile stress. | |

| Tearing resistance | ISO 34 | kN/m | 1,8 | 1,8 | 5,9 | 3,8 | 5,2 | Minimum tensile stress required to tear a pre-slit sample. |

| Abrasion resistance | ISO 5470 (1999) Taber 1000 revs/H22 | mg/100u | 89 | 89 | 45 | 68 | 62 | Ability to resist to abrasion. The figure shows the quantity of product destroyed after a certain number of abrasive cycles. |

| Melting temperature | - | °C | 150 to 170 | 150 to 170 | 170 | 150 to 170 | 150 to 170 | Temperature at which a substance changes from solid to liquid state. |

| °F | 302 to 338 | 302 to 338 | 338 | 302 to 338 | 302 to 338 | |||

| Pouring temperature | - | °C | 140 to 150 | 140 to 150 | 170 | 140 to 150 | 140 to 150 | Temperature at which the material should be poured onto the master. |

| °F | 284 to 302 | 284 to 302 | 338 | 284 to 302 | 284 to 302 | |||

| Density | ISO 1183 | g/cm3 | 1,13 | 1,13 | 1,02 | 1,13 | 1,11 | Mass per unit volume. |

The data contained in this technical specification is given for information only and is based on our current knowledge of the products concerned.

This information given to our customer in good faith to inform him and to help him in his search, does not constitute any formal or implicit guarantees as to its use.