What are you looking for?

BALLISTIFLEX

| Self-healing material |

| Elastic, resistant & durable to many impacts |

| Reduce the sound of bullet's impact |

| Lead dust containment and better aspiration |

| Safety equipment in shooting stand |

Formats

- Panels

- Red, yellow, grey, white or black available

| Min | Max | |

| Width | 500 mm | 1,5 m |

| Thickness | 5 mm | 12 mm |

| Length | 20 m | 20 m |

About Ballistiflex

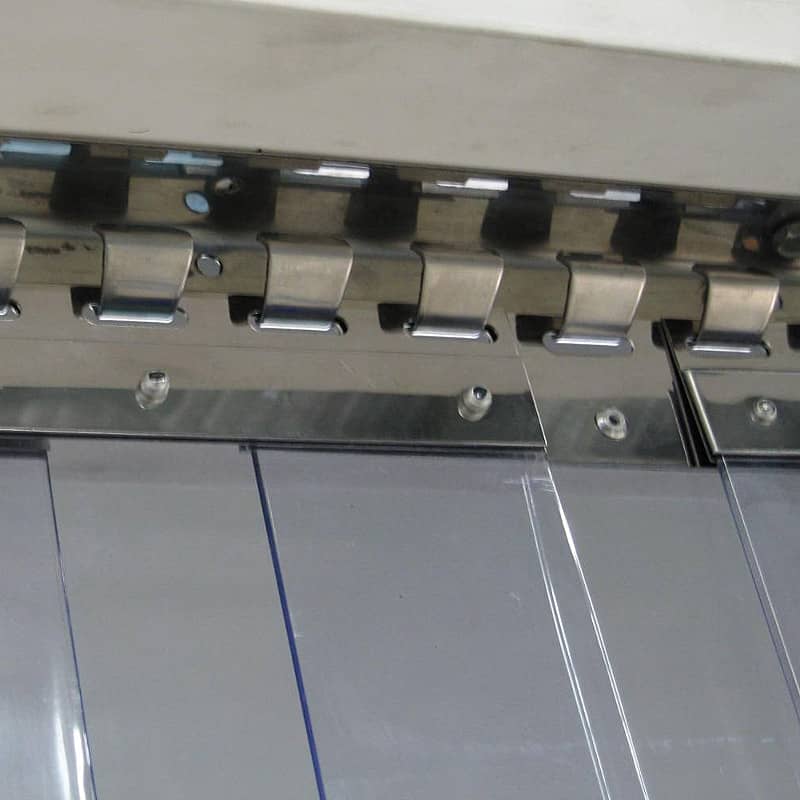

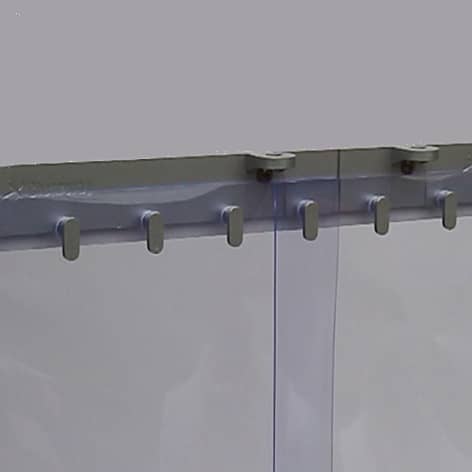

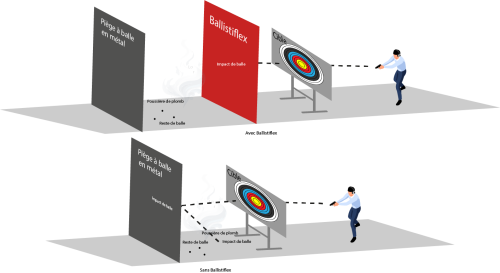

Ballistiflex is a self-healing flexible PVC material designed for use as an anti-return strip in shooting ranges. When a projectile penetrates Ballistiflex, it experiences a significant reduction in speed and energy. The heat generated by the bullet causes the hole to close quickly, demonstrating the material's unique self-healing capability. Ballistiflex can self-repair even after multiple impacts in the same spot.

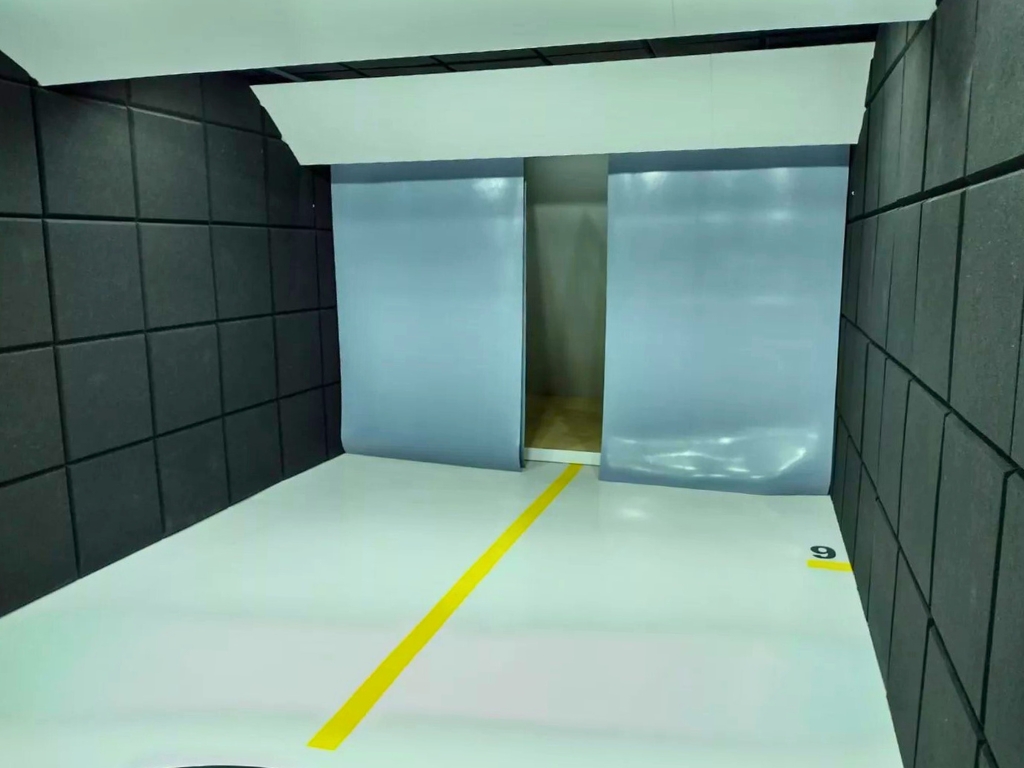

This innovative material not only absorbs and dissipates the energy of a bullet but also prevents projectiles from ricocheting off the back wall. The strip intercepts the bullet on its return, ensuring it does not pass through again. This is because the projectile loses most of its energy during its initial passage through the strip, enhancing safety by preventing projectiles from returning to the firing zone.

Ballistiflex contributes to reduce the sound level of bullets impacts and helps to confine the lead dust in the bullet trap for better venting.

Applications

Hardware

Why Choose Ballistiflex ?

Safety is the top priority in firing ranges, requiring strict compliance with rules and precautions to protect shooters and other personnel from hazardous projectiles.

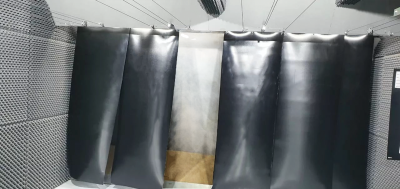

Ballistiflex is widely employed in shooting ranges as a highly effective anti-return curtain, serving to prevent bullets from rebounding off the back wall towards the shooter.

Common Applications:

- Police training facilities

- Indoor firing ranges

- Gun licensing facilities

- Military training facilities

- Outdoor firing ranges

Prevent Ricochets

Ballistiflex ensures safety by creating a barrier that stops projectiles from returning to the shooter. It reduces projectile energy, preventing ricochets or rebounds. Even low-energy ricochets can’t pass through the PVC again, maintaining a safe environment.

Prevent Shrapnel and Dust

Ballistiflex minimizes shrapnel and ballistic dust by using soft PVC, which absorbs most of the projectile's energy, preventing it from fragmenting. The PVC also captures projectile dust, keeping the range clean and safe.

Reduces Noise Pollution

Ballistiflex reduces noise pollution in firing ranges by slowing projectiles and using soft PVC to minimize impact noise. It also acts as a sound-suppressing barrier, cutting echoes and reducing sound transmission by 35dB, enhancing ear safety for shooters and minimizing disturbances nearby.

Self-Healing Properties

Ballistiflex has a self-repairing capability, closing gaps made by projectiles. The heat generated as projectiles pass through the PVC causes the material to weld shut, even after repeated impacts, ensuring durability and a longer lifespan.

Technical Datasheet

| Properties | Standard | Unit | Value | Description |

| Shore A hardness | EN ISO 868 | Sh A | 76 | Index based on a flat indenter's penetration depth. Scale from 0 (Soft) to 100 (Hard). |

| Tearing resistance | DIN 53515 | N/mm | 32 | Minimum tensile stress required to tear a pre-slit sample. |

| Tensile strength at break | ASTM D 638 EN ISO 527 | N/mm² | 13 | Maximum tensile stress that a material can be subjected to before break. |

| Elongation at break | % | 370 | Elongation of the specimen at the break point under tensile stress. | |

| Residual elong. (after break) | % | 72 | Permanent elongation of the specimen measured after rupture in a tensile test. | |

| Thermal conductivity | ASTM C 177 | W/m.K | 0,16 | Ability to conduct heat. The Lower it is, the more insulation. |

| Vicat softening temp. | EN ISO 306 | °C | 48 | Temperature at which the specimen is penetrated to a depth of 1 mm by a 1 kg flat indenter of 1 sq. mm. |

| Specific heat capacity | ISO 11357 | kJ/kg.K | 1,6 | Heat energy required to increase the temperature of one kilogram of the material by one degree Celsius. |

| Sound reduction | DIN 52210 | dB | >35 | Average sound level (freq. 0,1 to 3,2 kHz) decreased by a 1,76 sq.m. and 5 mm thick PVC curtain. |

| Reaction to fire | EN 13501-1:2007 | - | - | Standard classifications of material self-extinguishing and resistance to combustion. |

| Light transmittance | ASTM D 1003 | % | 0 | Visible light rate transmitted through the material. |

| UV resistance | ISO4892 | - | Yes | Ability to resist to UV (Sun, welding arc). |

| Surface resistivity | ASTM D257 | .1010 Ω/□ | 3 | Material surface electric resistivity measured with a 100 V direct voltage. |

| Water absorption | EN ISO 62 | % | -0,2 | Material mass variation after exposure to humid conditions. (<0 if released / >0 if absorbed) |

| Density | ASTM D 792 | g/cm3 | 1,18 | Mass per unit volume. |

The data contained in this technical specification is given for information only and is based on our current knowledge of the products concerned.

This information given to our customer in good faith to inform him and to help him in his search, does not constitute any formal or implicit guarantees as to its use.