What are you looking for?

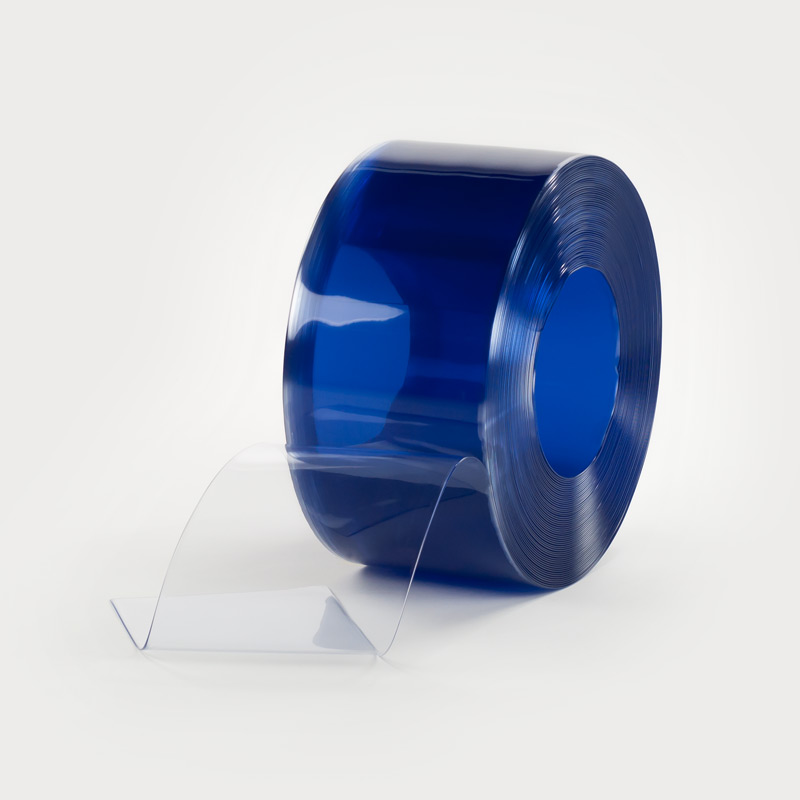

Semi-Rigid PVC

| Transparency/clarity |

| Flexibility |

| Thermal insulation |

| Noise insulation |

| Long durability |

| Impact & scratch resistance |

| Environment friendly & recyclable |

Formats

- Rolls, strips, curtains, panels and films

- Smooth, ribbed, reinforced, rounded edges, matt surface.

| Min | Max | |

| Width | 75 mm | 2.2 m |

| Thickness | 0.3 mm | 12 mm |

| Length | 20 m | 100 m |

About Semi-Rigid

Semi-Rigid PVC is used as “Semi-Rigid Glass”. It is offering clarity, brightness and adaptable ability to be bent or rolled-up.

Semi-Rigid PVC is most recommended to achieve flexible windows in roll up doors, rapid doors, automatic doors, semi-rigid panels for swing doors or strips doors in warm weather countries.

Applications

Hardware

Why Use Semi-Rigid PVC?

Semi-Rigid PVC has a variety of uses but is most commonly used as PVC swing doors, acting as a thermal insulating barrier in doorways, while still allowing pedestrian to pass through freely.

This often occurs in warehouses or factories, where it is essential for traffic to move freely through doorways, while also ensuring that the doorways are insulated to keep the warehouse or factory warm and sealed

Common Applications and Benefits

Swing doors with Semi-Rigid PVC:

Swing doors are commonly used in refrigeration environments such as walk-in coolers and freezers. They are designed to maintain the integrity of the refrigerated space while providing easy access for personnel and equipment.

The use of a Semi-Rigid PVC increases the rigidity of the panel and provides better hold of the door when opening.

High-Speed Roll-Up Doors:

These are designed for fast operation and are commonly used in high-traffic areas to improve efficiency and reduce air exchange between different environments.

High-speed roll-up doors made with PVC are often used in cleanrooms, food processing areas, and places where hygiene is paramount. They offer easy cleaning and maintenance.

Warehouse and Loading Docks:

PVC strips are installed at warehouse entrances and loading dock areas to create barriers that block dust, insects, and outside elements while facilitating the smooth flow of goods and vehicles. They also help maintain indoor temperature levels and reduce noise from external sources.

The use of Semi-Rigid PVC is particularly recommended when the outside temperature is hot, whereas flexible PVC will be too sticky due to the effect of the temperature.

Technical Datasheet

| Properties | Standard | Units | Standard | Description |

| Light transmittance | ASTM D 1003 | % | 85 | Visible light rate transmitted through the material. |

| Shore A hardness | EN ISO 868 | Sh A | 85 to 95 | Index based on a flat indenter's penetration depth. Scale from 0 (Soft) to 100 (Hard). |

| Tearing resistance | DIN 53515 | N/mm | 50 | Minimum tensile stress required to tear a pre-slit sample. |

| Tensile strength at break | ASTM D 638 EN ISO 527 | N/mm² | 16 | Maximum tensile stress that a material can be subjected to before break. |

| Elongation at break | % | 340 | Elongation of the specimen at the break point under tensile stress. | |

| Residual elong. (after break) | % | 68 | Permanent elongation of the specimen measured after rupture in a tensile test. | |

| Thermal conductivity | ASTM C 177 | W/m.K | 0,16 | Ability to conduct heat. The lower it is, the more insulation. |

| Cold bend brittle temp. | ISO 8570 | °C | -35 | Temperature at which the specimen break under torsion stress. Brittle point (CLASH & BERG). |

| Min. usage temp. | EN 1876 | °C | -15 | Temperature range where material keeps its mechanical properties (flexibility). |

| Max. usage temp. | °C | +50 | ||

| Specific heat capacity | ISO 11357 | kJ/kg.K | 1,6 | Heat energy required to increase the temperature of one kilogram of the material by one degree Celsius. |

| Sound reduction | DIN 52210 | dB | >35 | Average sound level (freq. 0,1 to 3,2 kHz) decreased by a 1,76 sq.m. and 5 mm thick PVC curtain. |

| Reaction to fire | EN 13501-1 | Class | - | Standard classifications of material self-extinguishing and resistance to combustion. |

| UV/IR filter | ISO 25980 | - | - | Ability to filter welding rays allowing the use of this material as a welding protection screen. |

| UV resistance | ISO4892 | - | Yes | Ability to resist to UV (Sun, welding arc). |

| Surface resistivity | ASTM D257 | .1010 Ω/□ | - | Material surface electric resistivity measured with a 100 V direct voltage. |

| Water absorption | EN ISO 62 | % | -0,2 | Material mass variation after exposure to humid conditions. (<0 if released / >0 if absorbed) |

| Anti-insect | - | - | - | Special ability to keep insects away.(Food processing plants, tropical regions) |

| Density | ASTM D 792 | g/cm3 | 1,22 | Mass per unit volume. |

Free download

- FLEXIBLE VINYL - NON-PHTHALATE PLASTICIZER (EN).pdf

- FLEXIBLE VINYL - SOLUTION FOR BUILDING (EN).pdf

- FLEXIBLE VINYL - SOUND REDUCTION (EN).pdf

- FLEXIBLE VINYL - THICKNESS & THERMAL INSULATION (EN).pdf

- FLEXIBLE VINYL - THERMAL INSULATION (EN).pdf

- FLEXIBLE VINYL - STABILIZERS & DURABILITY (EN).pdf

- PLASTIC MATERIALS & EARTH’S ENERGY RESOURCES (EN).pdf

- PLASTIC MATERIALS & GLOBAL WARMING (EN).pdf

- PLASTIC MATERIALS & OIL RESSOURCES (EN).pdf