What are you looking for?

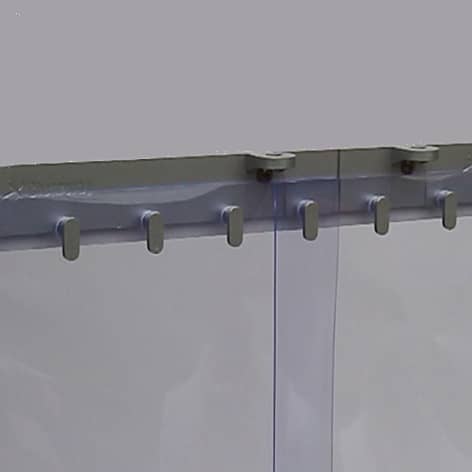

STOP-BAC Anti-Bacterial PVC

| Antibacterial, ISO 22196 compliant |

| Transparency |

| Noise insulation |

| Long durability |

| Impact & scratch resistance |

| Environment friendly & recyclable |

Formats

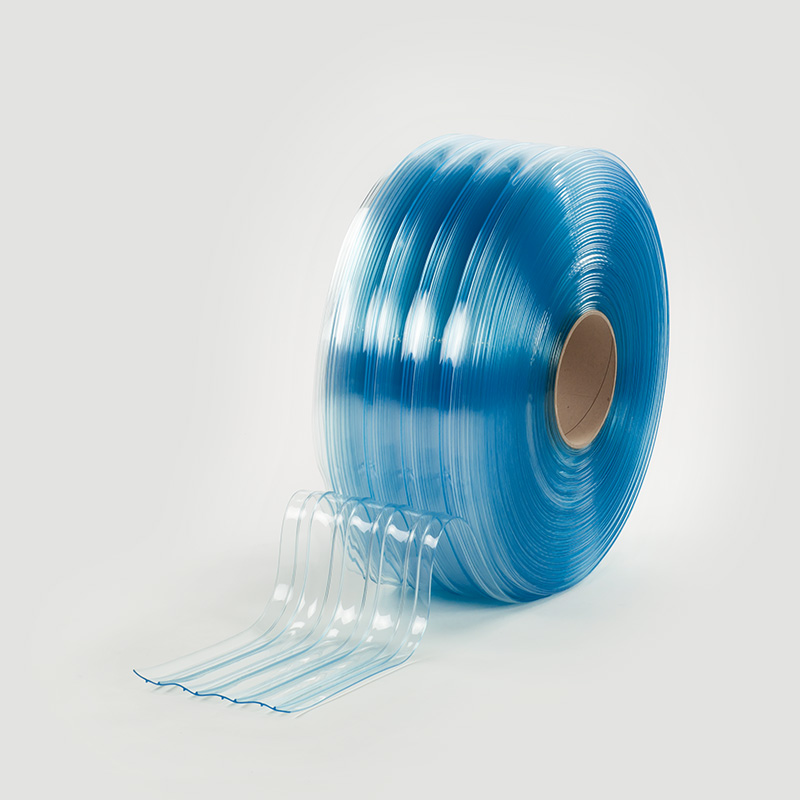

- Rolls, strips, curtains, panels and films

- Smooth, ribbed, reinforced, rounded edges, matt surface.

| Min | Max | |

| Width | 75 mm | 2.2 m |

| Thickness | 0.3 mm | 12 mm |

| Length | 20 m | 100 m |

About STOP-BAC®

Extruflex STOP-BAC is treated with antimicrobial agents that inhibit the growth of bacteria, mold, and mildew. It provides continuous protection against microbial contamination.

STOP-BAC complies with the International ISO 22196 and Japanese JIS Z 2801 standards to guarantee the highest Antibacterial effect.

STOP-BAC is prevents the development of bacterial niches and their proliferation in sensitive areas.

It is recommended in slaughterhouses, food preparation and food processing workshops, restaurants, hospitals, pharmaceutical laboratories, health centers, schools, industrial and commercial shops, etc…

Applications

Why Choose STOP-BAC ?

STOP-BAC PVC offers substantial advantages for workplaces necessitating pristine and bacteria-free environments.

This specialised PVC formulation possesses the capability to eradicate 99.9% of bacteria, viruses, and various microbial organisms upon contact, thereby effectively curbing the transmission of diseases and illnesses.

This attribute assumes particular significance within workplaces susceptible to disease transmission or any form of contamination that could compromise both human well-being and the company's reputation.

Common Applications

- Hospitals

- Health centres

- Food processing

- Slaughterhouses

- Restaurants

- Pharmaceutical laboratories

Prevent Risk Of Infection And Contamination

Approximately 13.6% of global deaths are attributed to bacterial infections, ranking as the second leading global cause of mortality.

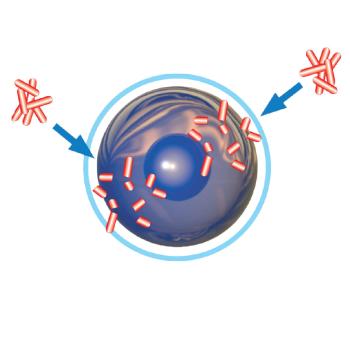

Extruflex addresses infectious risk by integrating an antibacterial agent into its flexible vinyl compound to create anti-bacterial PVC.

Our anti-bacterial flexible PVC products effectively curtail the transmission of bacteria and viruses, helping prevent outbreaks of Salmonella, E-Coli, and Campylobacter.

This ensures elevated hygiene standards and safeguards for both your staff and customers.

Safer Workplaces

The adoption of antibacterial PVC is strongly encouraged to enhance workplace hygiene, benefiting both employees and customers alike.

Antibacterial flexible PVC is ideally suited for environments prioritising cleanliness and sterile workstations, including hospitals,restaurants, and healthcare facilities.

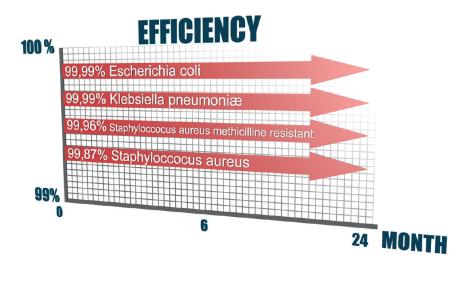

Antibacteria efficiency

Extruflex takes a proactive approach to combat workplace disease and infections by integrating an antibacterial agent into its soft vinyl, effectively eliminating 99.9% of bacteria upon contact.

This innovative anti-bacterial technology is integrated into the vinyl matrix itself, allowing the surface to retain its antibacterial properties over an extended duration.

The vinyl matrix disrupts the bacteria's outer membrane, resulting in bacterial eradication upon contact with the PVC.

Importantly, this anti-bacterial agent is seamlessly incorporated during the manufacturing process, ensuring continuous effectiveness without the need for reapplication, providing long-lasting antibacterial protection that remains active for many years.

Continuous Protection After Multiple Washes

Even after multiple wash cycles, the antibacterial agent remains fully active, ensuring lasting protection against all forms of bacterial growth in your workplace.

Focus On ISO 22196

STOP-BAC is compliant with the ISO 22196:2011 standard.

Its efficiency has been tested over a period of 2 years with 99.9% bacterial reduction.

Swabs from general day-to-day surfaces are gathered and then added to Petri dishes and exposed to temperatures of 37°C with relative humidity greater than 90%.

This allows the bacteria to multiply and grow. After 24 hours, the bacterial colonies are counted and recorded.

Then a second batch of swabs are taken from STOP-BAC PVC exposed to similar conditions and areas as the first test surfaces. These are then also exposed to temperatures of 37°C with relative humidity greater than 90% for 24hours.

The bacterial colonies are then counted and compared to test one to compare the STOP-BAC PVC's effectiveness.

In the STOP-BAC tests conducted in the past, 99.9 % of the bacteria had been eliminate.

This same test was conducted over a 2 year period in order to make sure that the effectiveness of the STOP-BAC PVC was still effective over this time period.

The results showed that STOP-BAC worked effectively, killing 99.9% of all bacteria, over this time period.

Technical datasheet

| Properties | Standard | Units | Standard | Description |

| Light transmittance | ASTM D 1003 | % | 85 | Visible light rate transmitted through the material. |

| Shore A hardness | EN ISO 868 | Sh A | 80 | Index based on a flat indenter's penetration depth. Scale from 0 (Soft) to 100 (Hard). |

| Tearing resistance | DIN 53515 | N/mm | 50 | Minimum tensile stress required to tear a pre-slit sample. |

| Tensile strength at break | ASTM D 638 EN ISO 527 | N/mm² | 16 | Maximum tensile stress that a material can be subjected to before break. |

| Elongation at break | % | 340 | Elongation of the specimen at the break point under tensile stress. | |

| Residual elong. (after break) | % | 68 | Permanent elongation of the specimen measured after rupture in a tensile test. | |

| Thermal conductivity | ASTM C 177 | W/m.K | 0,16 | Ability to conduct heat. The lower it is, the more insulation. |

| Cold bend brittle temp. | ISO 8570 | °C | -35 | Temperature at which the specimen break under torsion stress. Brittle point (CLASH & BERG). |

| Min. usage temp. | EN 1876 | °C | -15 | Temperature range where material keeps its mechanical properties (flexibility). |

| Max. usage temp. | °C | +50 | ||

| Specific heat capacity | ISO 11357 | kJ/kg.K | 1,6 | Heat energy required to increase the temperature of one kilogram of the material by one degree Celsius. |

| Sound reduction | DIN 52210 | dB | >35 | Average sound level (freq. 0,1 to 3,2 kHz) decreased by a 1,76 sq.m. and 5 mm thick PVC curtain. |

| Reaction to fire | EN 13501-1 | Class | - | Standard classifications of material self-extinguishing and resistance to combustion. |

| UV/IR filter | ISO 25980 | - | - | Ability to filter welding rays allowing the use of this material as a welding protection screen. |

| UV resistance | ISO4892 | - | Yes | Ability to resist to UV (Sun, welding arc). |

| Surface resistivity | ASTM D257 | .1010 Ω/□ | 30 | Material surface electric resistivity measured with a 100 V direct voltage. |

| Water absorption | EN ISO 62 | % | -0,2 | Material mass variation after exposure to humid conditions. (<0 if released / >0 if absorbed) |

| Anti-bacterial | ISO 22196 | - | Yes | Anti-bacterial surface |

| Density | ASTM D 792 | g/cm3 | 1,22 | Mass per unit volume. |

Free download

- STOP-BAC - REF459 - BROCHURE (EN).pdf

- FLEXIBLE VINYL - NON-PHTHALATE PLASTICIZER (EN).pdf

- FLEXIBLE VINYL - SOLUTION FOR BUILDING (EN).pdf

- FLEXIBLE VINYL - SOUND REDUCTION (EN).pdf

- FLEXIBLE VINYL - THICKNESS & THERMAL INSULATION (EN).pdf

- FLEXIBLE VINYL - THERMAL INSULATION (EN).pdf

- FLEXIBLE VINYL - STABILIZERS & DURABILITY (EN).pdf

- PLASTIC MATERIALS & EARTH’S ENERGY RESOURCES (EN).pdf

- PLASTIC MATERIALS & GLOBAL WARMING (EN).pdf

- PLASTIC MATERIALS & OIL RESSOURCES (EN).pdf