What are you looking for?

STOP-INSECT PVC

| Transparency |

| High surrounding repellency effect |

| Kills 100% of the mosquitoes in contact with the vinyl |

| Human safe, repulsive agent recommended by the WHO in the 200 essential medicines |

Formats

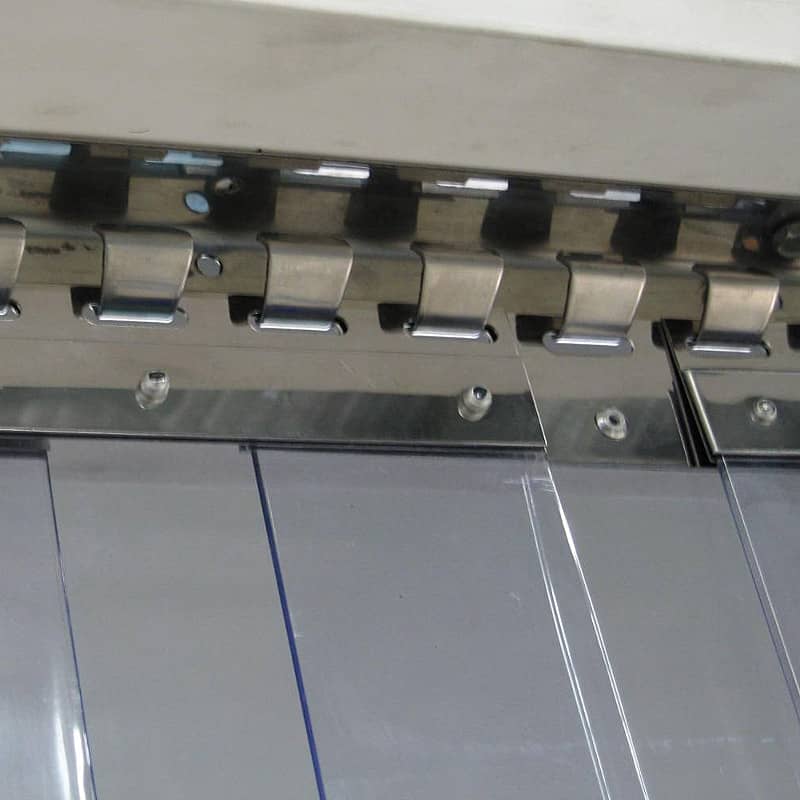

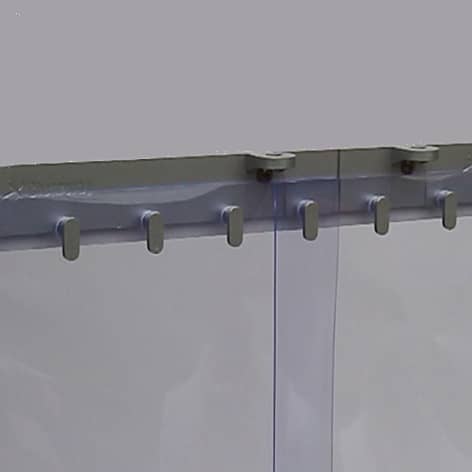

- Rolls, strips, curtains, panels and films

- Ribbed, reinforced, rounded edges, mat surface

| Min | Max | |

| Width | 75 mm | 2.2 m |

| Thickness | 0.3 mm | 12 mm |

| Length | 20 m | 100 m |

About STOP-INSECT®

Applications

Why Use Stop-Insect PVC?

The Extruflex STOP-INSECT PVC range, is engineered with Anti-Insect properties added into the flexible PVC, while preserving its inherent attributes, including optical clarity, luminosity, durability, flexibility, and robust impact resistance.

These innovative solutions adeptly repel approximately 80% of mosquitoes and administer a lethal blow to any mosquito that comes into contact with the vinyl, guaranteeing a 100% mortality rate over a 12-month period. Additionally, STOP-INSECT PVC serves as an effective deterrent against spiders, ticks, chiggers, mites, and scabiesmites.

Common applications

- Animal Welfare

- Agriculture / Farming Industry Food

- Supermarkets/Retail

- Manufacturing plants

- Warehousing Facilities

- Outside Operations / Pest Control

- Health Centres & Public Buildings

Fight against insects spreading disease

Pest control is a very crucial aspect of safety within the food industry or for areas that get a lot of disease-spreading mosquitoes.

Insects can spread serious diseases and therefore pest control is extremely important in vulnerable areas or industries. The U.S. Centers for Disease Control and Prevention calls mosquitoes the “world’s deadliest animal.” It’s a well deserved title because vector-borne diseases, caused by mosquitoes cause more than 700,000 deaths worldwide every year. Mosquitoes are capable of spreading at least 6 dangerous diseases, some of which include malaria, dengue, yellow fever, and the Zika virus.

STOP-INSECT PVC strips or sheets aid in the reduction of unwanted insects in factories, such as mosquitoes, ants, spiders, scorpions, mites, ticks, fleas or cockroaches. They will also effectively protect your personnel against a build-up of these insects.

Kills Insects on Contact

STOP-INSECT PVC has been designed to keep away insects with its specially designed Anti-Insect properties, acting as a barrier to prevent insects from entering houses and workplaces.

The STOP-INSECT PVC also kills all insects on contact, ensuring that insects do not enter through doorways or partitions.

These curtains are also great barriers against noise, dust, bugs, birds and other nuisances.

STOP-INSECT PVC can help with pest control

STOP-INSECT PVC Curtain Rolls and stripsrepel insects due to the anti-insect properties of the PVC. The PVC can also act as a barrier to prevent insects from passing through doorways or partitions.

Extruflex has incorporated an anti-insect agent in its soft vinyl compound. This agent acts as a deterrent for insects and if any insects do make it onto the PVC, it will kill the insects on contact with the PVC.

The Active Agent in the STOP-INSECT PVC

The neuro-toxin agent in the anti-insect PVC slowly releases over time, keeping a consistent effect.

Anti-insect PVC strips will need to be replaced every 24 months for optimum use as the agent in the PVC will begin to be less effective after this 24-month period.

The agent achieves two main effects in the fight against insects:

- Active repellency:80% efficiency during at least 24 months.

- Kills on contact: 100% of mosquitoes which approach or contact the Anti-Insect PVC strip or sheet will be killed.

Completely Safe for Humans

The agent within the STOP-INSECT PVC Curtain Rolls is completely safe for humans and recommended by the World Health Organisation.

STOP-INSECT PVC is specifically recommended for strip curtains and partitions that will encounter insects.

STOP-INSECT PVC will efficiently repel insects and prevent infiltration of areas like schools, hospitals, health centres, factories, industrial workshops, commercial shops, public buildings and private residences.

Technical datasheet

| Properties | Standard | Units | Standard | Description |

| Light transmittance | ASTM D 1003 | % | 85 | Visible light rate transmitted through the material. |

| Shore A hardness | EN ISO 868 | Sh A | 80 | Index based on a flat indenter's penetration depth. Scale from 0 (Soft) to 100 (Hard). |

| Tearing resistance | DIN 53515 | N/mm | 50 | Minimum tensile stress required to tear a pre-slit sample. |

| Tensile strength at break | ASTM D 638 EN ISO 527 | N/mm² | 16 | Maximum tensile stress that a material can be subjected to before break. |

| Elongation at break | % | 340 | Elongation of the specimen at the break point under tensile stress. | |

| Residual elong. (after break) | % | 68 | Permanent elongation of the specimen measured after rupture in a tensile test. | |

| Thermal conductivity | ASTM C 177 | W/m.K | 0,16 | Ability to conduct heat. The lower it is, the more insulation. |

| Cold bend brittle temp. | ISO 8570 | °C | -35 | Temperature at which the specimen break under torsion stress. Brittle point (CLASH & BERG). |

| Min. usage temp. | EN 1876 | °C | -15 | Temperature range where material keeps its mechanical properties (flexibility). |

| Max. usage temp. | °C | +50 | ||

| Specific heat capacity | ISO 11357 | kJ/kg.K | 1,6 | Heat energy required to increase the temperature of one kilogram of the material by one degree Celsius. |

| Sound reduction | DIN 52210 | dB | >35 | Average sound level (freq. 0,1 to 3,2 kHz) decreased by a 1,76 sq.m. and 5 mm thick PVC curtain. |

| Reaction to fire | EN 13501-1 | Class | - | Standard classifications of material self-extinguishing and resistance to combustion. |

| UV/IR filter | ISO 25980 | - | - | Ability to filter welding rays allowing the use of this material as a welding protection screen. |

| UV resistance | ISO4892 | - | Yes | Ability to resist to UV (Sun, welding arc). |

| Surface resistivity | ASTM D257 | .1010 Ω/□ | 30 | Material surface electric resistivity measured with a 100 V direct voltage. |

| Water absorption | EN ISO 62 | % | -0,2 | Material mass variation after exposure to humid conditions. (<0 if released / >0 if absorbed) |

| Anti-insect | - | - | Yes | Special ability to keep insects away.(Food processing, plants, tropical regions) |

| Density | ASTM D 792 | g/cm3 | 1,22 | Mass per unit volume. |

Free download

- STOP-INSECT - REF423 - BROCHURE (EN).pdf

- FLEXIBLE VINYL - NON-PHTHALATE PLASTICIZER (EN).pdf

- FLEXIBLE VINYL - SOLUTION FOR BUILDING (EN).pdf

- FLEXIBLE VINYL - SOUND REDUCTION (EN).pdf

- FLEXIBLE VINYL - THICKNESS & THERMAL INSULATION (EN).pdf

- FLEXIBLE VINYL - THERMAL INSULATION (EN).pdf

- FLEXIBLE VINYL - STABILIZERS & DURABILITY (EN).pdf

- PLASTIC MATERIALS & EARTH’S ENERGY RESOURCES (EN).pdf

- PLASTIC MATERIALS & GLOBAL WARMING (EN).pdf

- PLASTIC MATERIALS & OIL RESSOURCES (EN).pdf