What are you looking for?

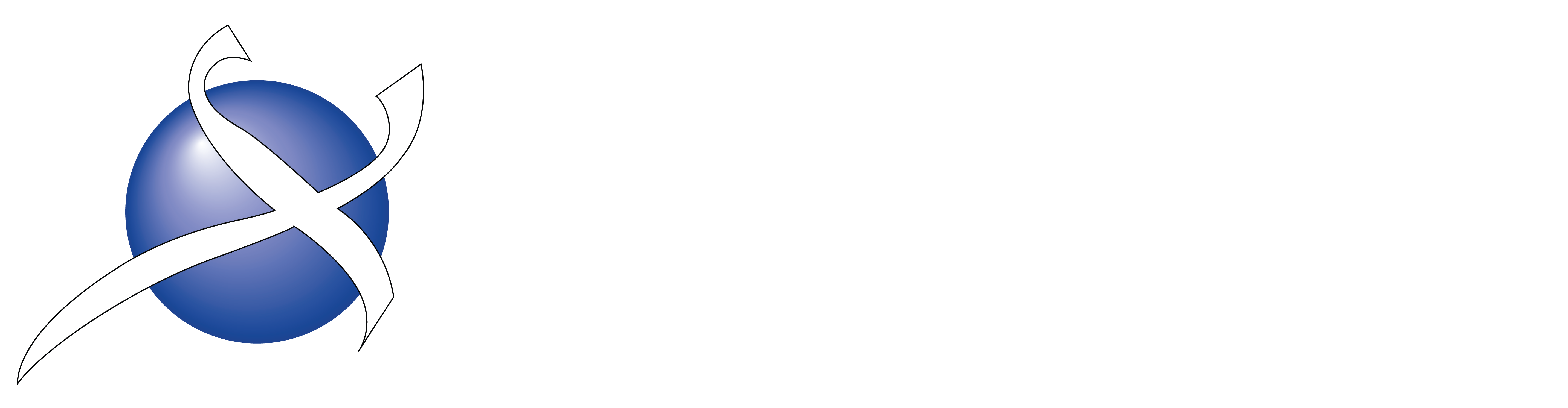

Clear PVC

| Transparency/clarity |

| Thermal insulation |

| Noise insulation |

| Long durability |

| Impact & scratch resistance |

| Environment-friendly & recyclable |

Formats

- Rolls, strips, curtains, panels and films

- Smooth, ribbed, reinforced, rounded edges, matt surface

| Min | Max | |

| Width | 75 mm | 2.2 m |

| Thickness | 0.3 mm | 12 mm |

| Length | 20 m | 100 m |

About Standard Clear

Extruflex's Standard Clear flexible PVC range offers the greatest clarity, brightness, durability, flexibility, and resistance to damage and chemicals.

Standard Clear flexible PVC is great for insulating doorways or cold rooms, providing temperature control wherever the flexible PVC is installed, allowing you to save money on your energy bills.

Our Standard Clear flexible vinyl materials are also extremely easy to clean. Like the entirety of the Extruflex flexible PVC range, the Standard Clear PVC range is 100% recyclable and is non-phthalate.

Applications

Why Use Standard Clear Flexible PVC?

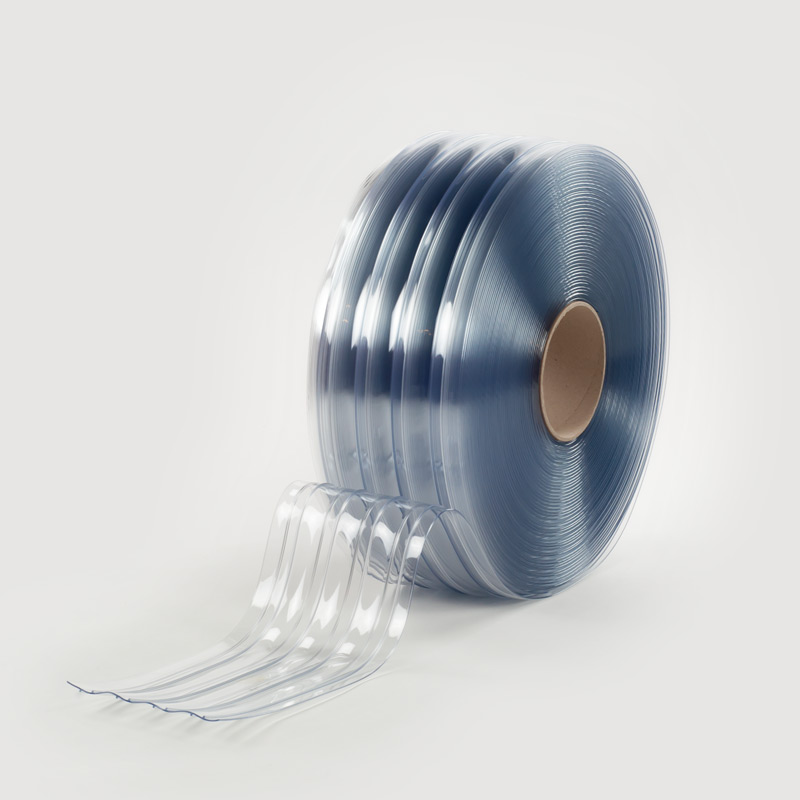

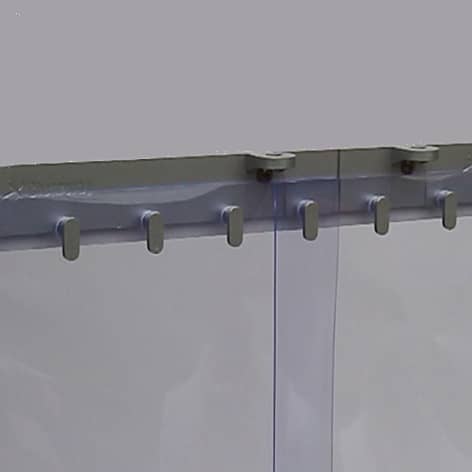

Standard Clear flexible PVC has a variety of uses but is most commonly used as PVC strip curtains or PVC swing doors, acting as a thermal insulating barrier in doorways, while still allowing pedestrian traffic, forklift traffic or industrial vehicles to pass through freely. It is also used in rapid high-speed doors as a vision panel (window).

In warehouses or factories especially, this enables free traffic flow without compromising insulation or sealing.

Common applications

- Strip Curtains or Partitions

- Manufacturing facilities

- Food processing plants

- Medical facilities

- Supermarkets/Retail

- Warehousing and distribution

Flexible PVC Helps Save You Money and Energy

Recognised as one of the premier thermal insulating plastics available, flexible PVC offers a cost-effective solution for insulating warehouses or factories.

Its inherent waterproof and air-tight properties further enhance its thermal insulation capabilities, preventing the intrusion of cold and wet weather through doorways.

The low thermal conductivity of flexible vinyl translates to substantial thermal energy savings, contributing to reduced energy bills while ensuring a comfortable environment for employees.

Opting for flexible PVC as a means of insulating doorways is a straightforward decision, given its cost-effectiveness, ease of installation, simple maintenance, and high replaceability in the event of damage.

Constant Insulation

PVC strip curtains or PVC swing doors are frequently employed in doorways to enhance insulation and protect buildings from the elements. Serving as an effective barrier, these installations help retain warmth within the structure.

Their operational flexibility allows for easy opening and closing, facilitating smooth traffic flow without the need for operators to dismount from forklifts to manually open warehouse doors. Additionally, these doors automatically close after passage, mitigating the risk of inadvertent oversight in leaving doorways open.

This feature ensures airtight insulation while simultaneously accommodating a seamless and unrestricted flow of traffic.

Sound Insulating Properties

Flexible PVC has sound insulating properties, able to reduce sound transmission.

This reduces the amount of noise heard on the other side of the PVC, drastically reducing the sound pollution in the area. The PVC material behaves like a soft viscoelastic mass that can absorb sound waves and dissipates its energy on contact with the PVC. This property of the PVC lets it absorb a wide range of sound frequencies, especially low frequency sound waves, better than other materials.

This reduces the noise produced in loud areas, such as factories, keeping workers and any neighbouring businesses happy.

- An average reduction of over -30 dB, which is equivalent to wearing mufflers

- 1 to 5 mm of thickness is enough to get a -30 dB reduction in sound

Special formats

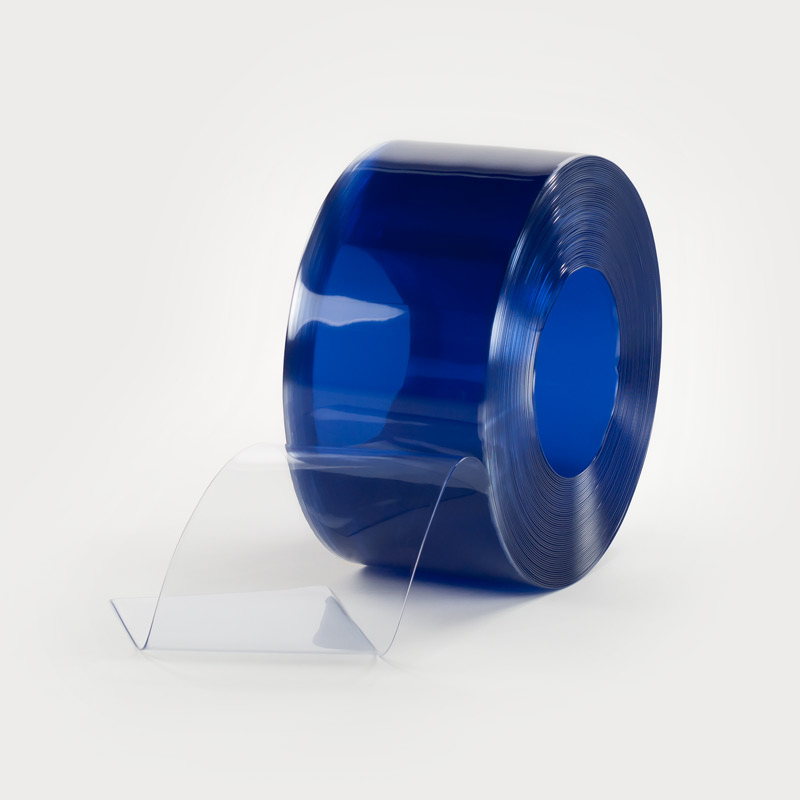

Ribbed PVC

Ribbed PVC has all the same properties as standard PVC except for the fact that it has small profiles (ribs)that prevent the curtain from sticking together.

The ribs also slightly reinforce the PVC making it a bit stronger and able to take more abuse than the standard PVC.

They still have all the qualities of the standard PVC, having excellent clarity, durability and flexibility.

Reinforced PVC Sheet

Reinforced PVC sheet is reinforced with a fibre mesh, to heavily reinforce the PVC and make it highly resistant to damage.

This lightweight but strong sheeting is extremely durable and able to withstand even the worst abuse. Although it is extremely durable due to the fiber mesh found inside it, it still allows light to pass through the PVC.

Reinforced PVC sheet has a variety of uses, a few of which include builders' dust sheeting, temporary window repairs, garden cloches or temporary windows when carrying out building work.

Technical datasheet

| Properties | Standard | Units | Standard | Description |

| Light transmittance | ASTM D 1003 | % | 85 | Visible light rate transmitted through the material. |

| Shore A hardness | EN ISO 868 | Sh A | 80 | Index based on a flat indenter's penetration depth. Scale from 0 (Soft) to 100 (Hard). |

| Tearing resistance | DIN 53515 | N/mm | 50 | Minimum tensile stress required to tear a pre-slit sample. |

| Tensile strength at break | ASTM D 638 EN ISO 527 | N/mm² | 16 | Maximum tensile stress that a material can be subjected to before break. |

| Elongation at break | % | 340 | Elongation of the specimen at the break point under tensile stress. | |

| Residual elong. (after break) | % | 68 | Permanent elongation of the specimen measured after rupture in a tensile test. | |

| Thermal conductivity | ASTM C 177 | W/m.K | 0,16 | Ability to conduct heat. The Lower it is, the more insulation. |

| Cold bend brittle temp. | ISO 8570 | °C | -35 | Temperature at which the specimen break under torsion stress. Brittle point (CLASH & BERG). |

| Min. usage temp. | EN 1876 | °C | -15 | Temperature range where material keep its mechanical properties (flexibility). |

| Max. usage temp. | °C | +50 | ||

| Vicat softening temp. | EN ISO 306 | °C | 50 | Temperature at which the specimen is penetrated to a depth of 1 mm by a 1 kg flat indenter of 1 sq. mm. |

| Specific heat capacity | ISO 11357 | kJ/kg.K | 1,6 | Heat energy required to increase the temperature of one kilogram of the material by one degree Celsius. |

| Sound reduction | DIN 52210 | dB | >35 | Average sound level (freq. 0,1 to 3,2 kHz) decreased by a 1,76 sq.m. and 5 mm thick PVC curtain. |

| Reaction to fire | EN 13501-1 | Class | - | Standard classifications of material self-extinguishing and resistance to combustion. |

| UV/IR filter | ISO 25980 | - | - | Ability to filter welding rays allowing the use of this material as a welding protection screen. |

| UV resistance | ISO4892 | - | Yes | Ability to resist to UV (Sun, welding arc). |

| Surface resistivity | ASTM D257 | .1010 Ω/□ | 30 | Material surface electric resistivity measured with a 100 V direct voltage. |

| Water absorption | EN ISO 62 | % | -0,2 | Material mass variation after exposure to humid conditions. (<0 if released / >0 if absorbed) |

| Anti-insect | - | - | - | Special ability to keep insects away.(Food processing plants, tropical regions) |

| Density | ASTM D 792 | g/cm3 | 1,22 | Mass per unit volume. |

This information given to our customer in good faith to inform him and to help him in his search, does not constitute any formal or implicit guarantees as to its use.

Free download

- FLEXIBLE VINYL - NON-PHTHALATE PLASTICIZER (EN).pdf

- FLEXIBLE VINYL - SOLUTION FOR BUILDING (EN).pdf

- FLEXIBLE VINYL - SOUND REDUCTION (EN).pdf

- FLEXIBLE VINYL - THICKNESS & THERMAL INSULATION (EN).pdf

- FLEXIBLE VINYL - THERMAL INSULATION (EN).pdf

- FLEXIBLE VINYL - STABILIZERS & DURABILITY (EN).pdf

- PLASTIC MATERIALS & EARTH’S ENERGY RESOURCES (EN).pdf

- PLASTIC MATERIALS & GLOBAL WARMING (EN).pdf

- PLASTIC MATERIALS & OIL RESSOURCES (EN).pdf