What are you looking for?

스크린플렉스

| Complies with ISO 25980:2023 and AWS F2.3M |

| Filters dangerous lights of arc welding |

| Fireproofed to protect people, equipment and buildings |

| Long durability |

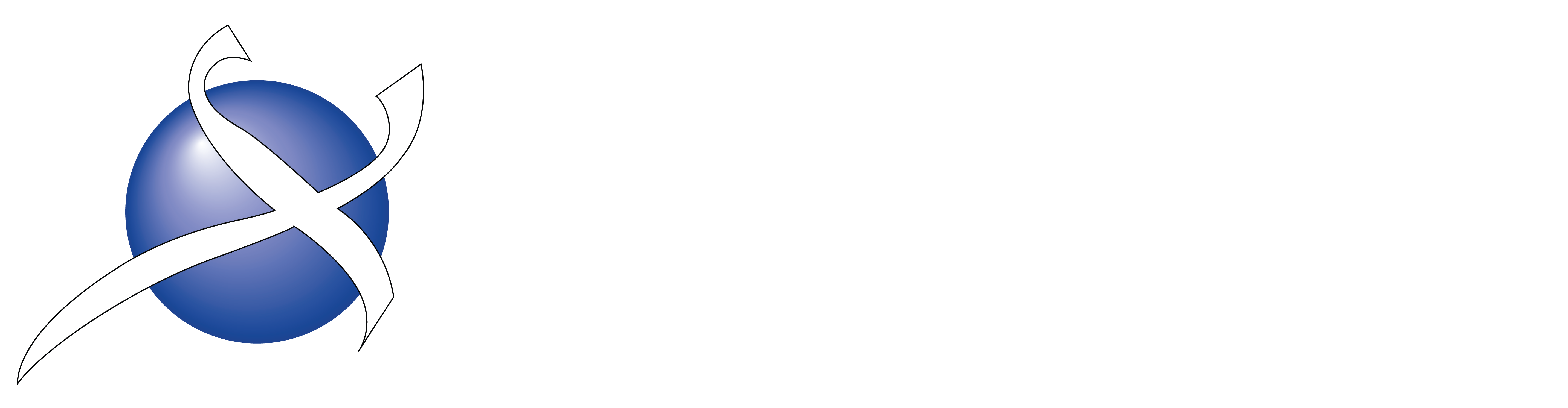

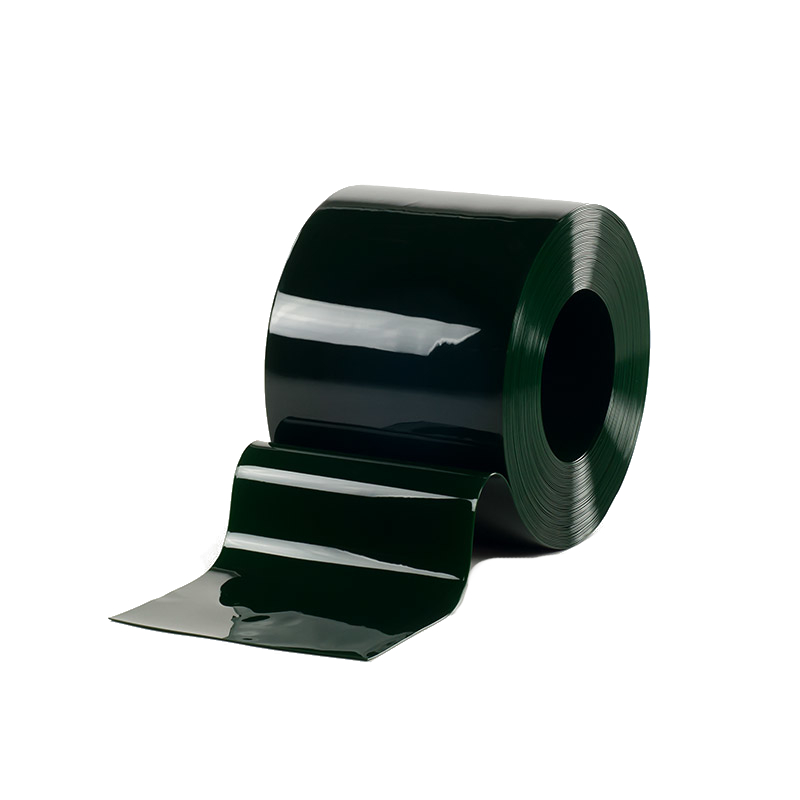

| Available in different colours and transparencies |

| Environment friendly & recyclable |

Formats

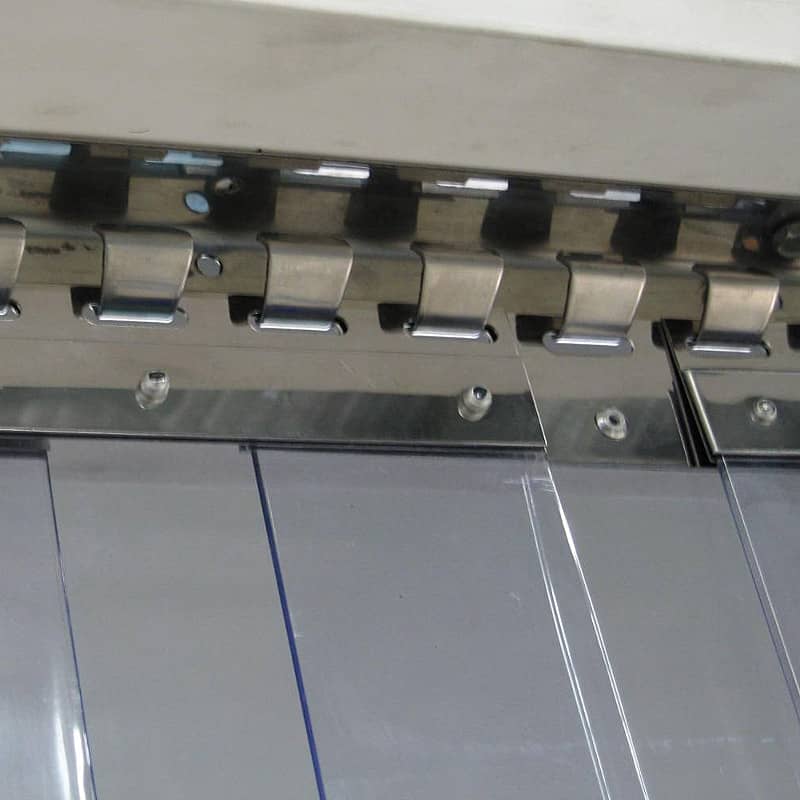

- Rolls, strips, curtains, panels and films

- Ribbed, reinforced, rounded edges, matt surface.

| Min | Max | |

| Width | 200 mm | 2.2 m |

| Thickness | 0.4 mm | 3 mm |

| Length | 20 m | 50 m |

About Screenflex®

Introducing Screenflex® PVC range, meticulously crafted for the welding industry to deliver robust protection against welding hazards, encompassing harmful UV radiation and spatter. Compliant with globally recognised "Health and Safety in Welding" standards, such as ISO 25980 and AWS F2.3M, this range upholds the hallmark qualities of Extruflex PVC, including durability, flexibility, and impact resistance.

Screenflex® is available in a range of colours and thicknesses, thoughtfully designed to meet transparency requirements while effectively blocking dirt and debris. Moreover, it offers thermal and sound insulation, contributing to an enhanced level of workplace comfort.

Why Choose Screenflex?

Screenflex® acts as a strong protective barrier, safeguarding observers and nearby personnel from dangerous arc light, radiation, and hot debris during welding. This innovative PVC material allows for safe observation of welders while protecting against exposure to UV radiation and harmful light wavelengths.

It is useful in various industries where close proximity to welding is common or secure monitoring of welders is essential. Screenflex® is a critical safety measure that enhances workplace safety and enables effective supervision in diverse industrial environments.

Common Applications:

- Outdoor Welding

- Manufacturing

- Outside Operations

- Welding Bays

- Engineering Factories

- Welding Training Centers

Complies safety standard

Screenflex meets ISO 25980 and AWS F2.3M requirements, making it a recommended safety solution for workplaces. These protective measures are designed to safeguard employees and business property from harmful radiation, heat, light, and fumes.

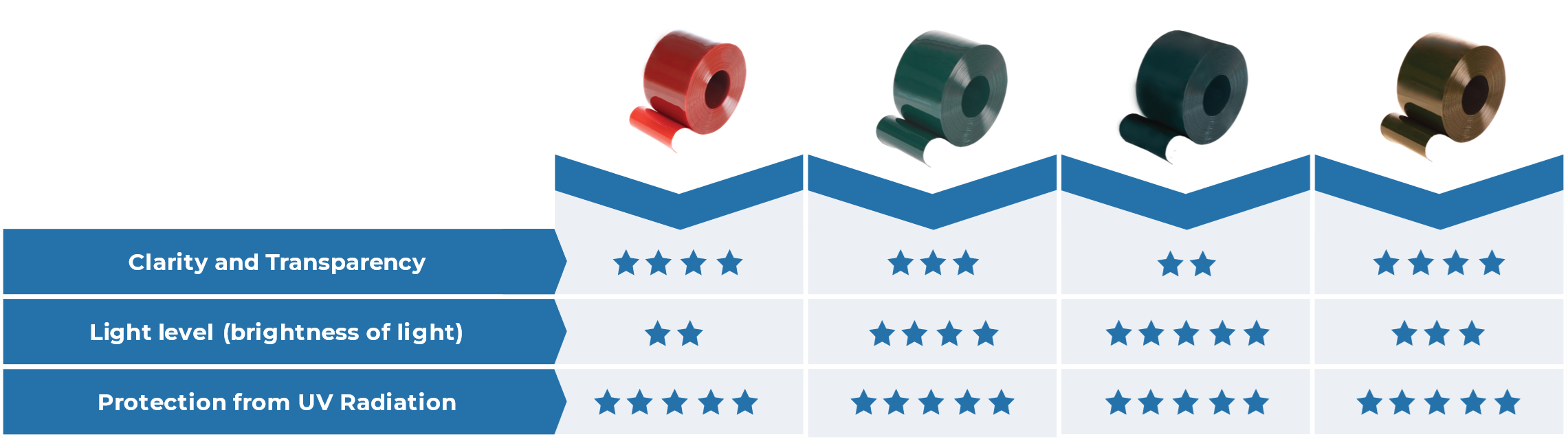

Which Colour is Best for Your Application?

Highly transparent PVC allows observers to clearly see welding activities, though the emitted light may be more intense. Conversely, less transparent Screenflex options significantly reduce external light, providing more comfort for observers and greater privacy for welders.

All Screenflex colors effectively shield against UV radiation, making any color suitable for this purpose.

The hazards of welding

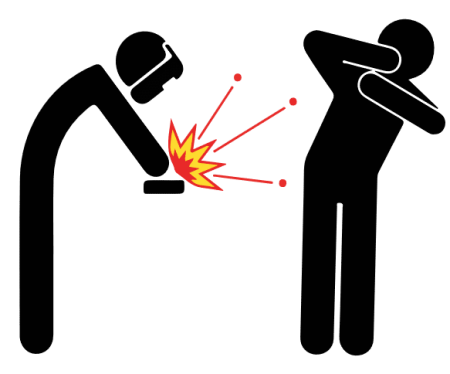

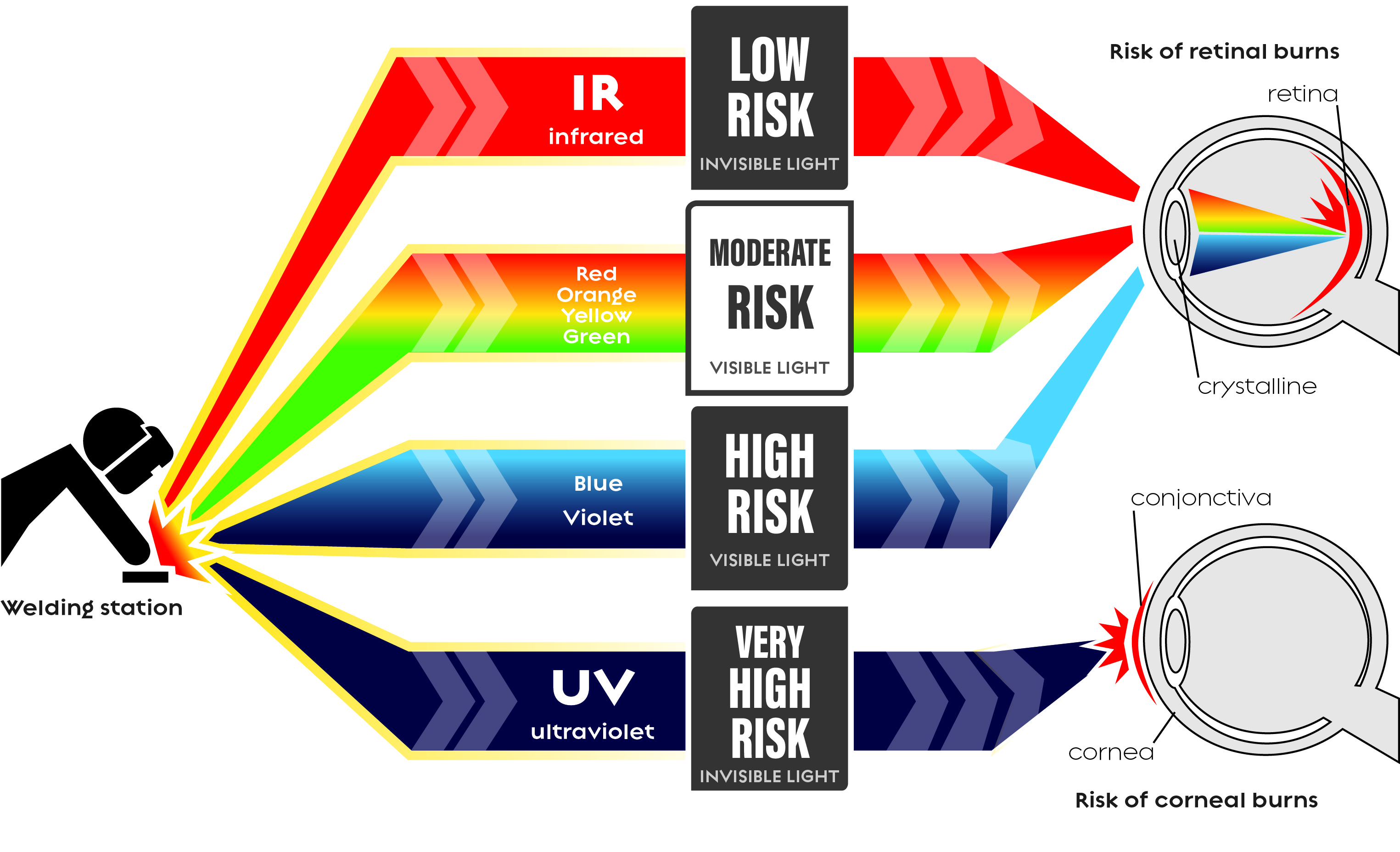

Hazards Caused by Light Radiation : During the welding process, an electric arc emits substantial ultraviolet, infrared, and blue light radiation, which can cause cicatrizing conjunctivitis, erythema, and other ocular lesions.

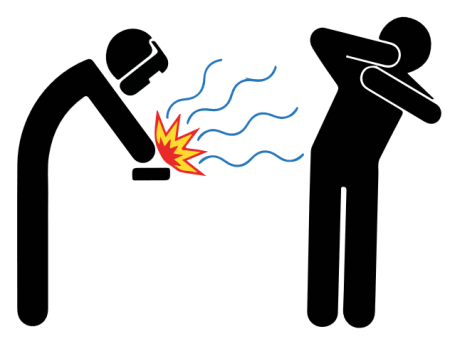

Screenflex Protects Onlookers From Radiation : Screenflex protective PVC absorbs hazardous radiation, both visible (like blue light) and invisible (such as infrared and ultraviolet radiation), enhancing workplace safety and ensuring all employees are shielded from the harsh radiation produced during the welding process.

Screenflex Protects Personnel and Property From Heated Metal and Fires : Molten metallic particles (weld spatter) can reach temperatures over 1,500 °C, posing significant burn risks and fire hazards. Screenflex welding screens prevent the spread of weld spatter, safeguarding the welder's work environment. These protective barriers greatly reduce the likelihood of fires and injuries, enhancing workplace safety and providing peace of mind.

The hazards of welding lights

A Safe Worker is a Happy Worker

Screenflex welding screens provide essential protection during welding, minimizing workplace hazards. Their semi-transparency provides the added advantage of enabling visual monitoring of welders from a safer vantage point, effectively distancing individuals from potential dangers.

Are Welding Screens Required?

They are vital for both compliance with health and safety regulations, as well as protecting your employees during welding, reducing workplace injuries and fires. Prioritising employee well-being and safety is paramount.

Technical Datasheet

| Properties | Standard | Units | Standard | Description |

| Light transmittance | ASTM D 1003 | % | ≤ 13 | Visible light rate transmitted through the material. |

| Shore A hardness | EN ISO 868 | Sh A | 80 | Index based on a flat indenter's penetration depth. Scale from 0 (Soft) to 100 (Hard). |

| Tearing resistance | DIN 53515 | N/mm | 55 | Minimum tensile stress required to tear a pre-slit sample. |

| Tensile strength at break | ASTM D 638 EN ISO 527 | N/mm² | 18 | Maximum tensile stress that a material can be subjected to before break. |

| Elongation at break | % | 300 | Elongation of the specimen at the break point under tensile stress. | |

| Residual elong. (after break) | % | 62 | Permanent elongation of the specimen measured after rupture in a tensile test. | |

| Thermal conductivity | ASTM C 177 | W/m.K | 0,16 | Ability to conduct heat. The Lower it is, the more insulation. |

| Cold bend brittle temp. | ISO 8570 | °C | -25 | Temperature at which the specimen break under torsion stress. Brittle point (CLASH & BERG). |

| Min. usage temp. | EN 1876 | °C | -15 | Temperature range where material keep its mechanical properties (flexibility). |

| Max. usage temp. | °C | +50 | ||

| Specific heat capacity | ISO 11357 | kJ/kg.K | 1,6 | Heat energy required to increase the temperature of one kilogram of the material by one degree Celsius. |

| Sound reduction | DIN 52210 | dB | >35 | Average sound level (freq. 0,1 to 3,2 kHz) decreased by a 1,76 sq.m. and 5 mm thick PVC curtain. |

| Reaction to fire | EN 13501-1 | - | Yes | Standard classifications of material self-extinguishing and resistance to combustion. |

| UV/IR filter | ISO 25980 | - | Yes | Ability to filter welding rays allowing the use of this material as a welding protection screen. |

| UV resistance | ISO4892 | - | Yes | Ability to resist to UV (Sun, welding arc). |

| Surface resistivity | ASTM D257 | .1010 Ω/□ | 30 | Material surface electric resistivity measured with a 100 V direct voltage. |

| Water absorption | EN ISO 62 | % | -0,2 | Material mass variation after exposure to humid conditions. (<0 if released / >0 if absorbed) |

| Anti-insect | - | - | - | Special ability to keep insects away.(Food processing plants, tropical regions) |

| Density | ASTM D 792 | g/cm3 | 1,25 to 1,30 | Mass per unit volume. |

This information given to our customer in good faith to inform him and to help him in his search, does not constitute any formal or implicit guarantees as to its use.