What are you looking for?

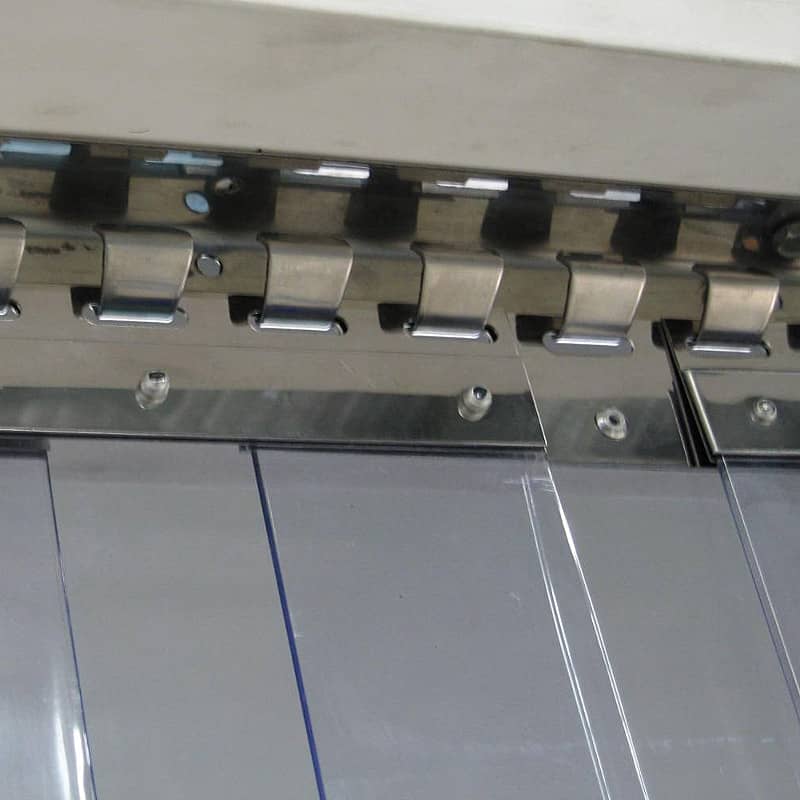

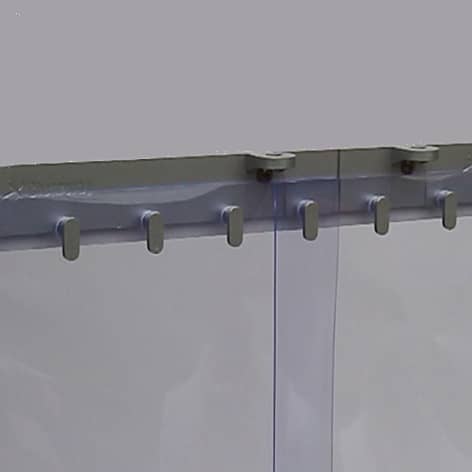

Fire Retardant PVC

| Fire-retardant |

| Transparency/clarity |

| Noise insulation |

| Long durability |

| Impact & scratch resistance |

| Environment-friendly & recyclable |

Formats

- Films, strips, curtains and panels

- Ribbed, reinforced, rounded edges, matt surface

| Min | Max | |

| Width | 75 mm | 2.2 m |

| Thickness | 0.3 mm | 12 mm |

| Length | 20 m | 100 m |

About Fire Retardant

Our Fire Retardant PVC range of products has fireproofing properties, to prevent the breakout and spread of accidental fires.

Fire Retardant PVC complies with regulations such as EUROCLASS, French M classification, German B classification or California Fire Marshal (CFM)

This is the perfect flexible PVC product if your environment needs fire-related protection or is exposed to an environment that needs to withstand a lot of heat. Extruflex's fire retardant PVC has all the same great qualities as the standard PVC product range, having the best clarity, brightness, durability and flexibility on the market.

Applications

Why Use Fire Retardant PVC?

Fire Retardant PVC has a large number of applications and should be used as an alternative to standard PVC if there are risks of open flames and flammable materials near the PVC.

This prevents fires from starting or spreading.

Fire Retardant PVC complies with international regulations such as EUROCLASS, M classification, B classification, California Fire Marshal, etc.

Common Applications

- Industrial warehousing

- Commercial warehousing

- Marquees

- Partitions

- Mining sector

- Outdoor barbeque areas

Prevent Fires

Fire Retardant PVC is recommended, near campfires, forges, candles or fireplaces. The fire retardant properties of the PVC prevent fires from starting and are therefore a great option for certain use cases where being near open flames is a possibility.

Fire Retardant PVC doesn't ignite as easily as other PVC products on the market and is therefore extremely safe to use.

How Does Fire Retardant PVC Work ?

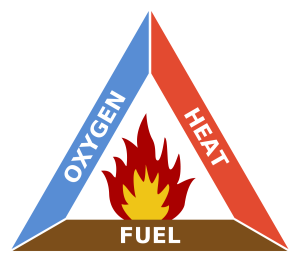

To stop a fire, simply remove or reduce one of the three components of the fire triangle:

- Heat Elimination

- Fuel Disposal

- Oxygen Elimination

In soft PVC, the fire retardants can promote the formation of a stable char layer on the surface of PVC.

This char layer acts as a thermal barrier, reducing heat transfer (HEAT) to the underlying material and slowing down the release of flammable volatiles(FUEL).

Euroclass

The Euroclass B classification indicates that the materials have a very low contribution to fire, standing out for their low flammability and their ability not to spread flames quickly.

To obtain this classification, materials must pass standardized tests, as the SBI (Single Burning Item) test and the flame test, showing low flame spread and limited heat production.

In addition, additional parameters such as smoke production (s1, s2, s3) and formation of flaming droplets (d0, d1, d2) are added to detail the performance.

These materials are commonly used in buildings where fire safety is crucial and to comply with strict fire safety standards in Europe.

Extruflex Fire-Retardant PVC can meet Euroclass B,s3-d0 classification.

French M2 fire test

The M2 fire rating is a French classification that evaluates the reaction of materials to fire, indicating that they are difficult to ignite.

Part of a scale ranging from M0 (incombustible) to M4 (easily flammable), M2 materials do not catch fire easily and contribute minimally to the spread of flames.

CFM (California Fire Marshal)

The California Fire Marshal vertical test is a fire safety assessment used to evaluate the flame resistance of materials, particularly for building interiors.

In this test, a material sample is mounted vertically and exposed to a standardized flame for a set period to measure flame spread, burning rate, and the duration of afterflame and afterglow.

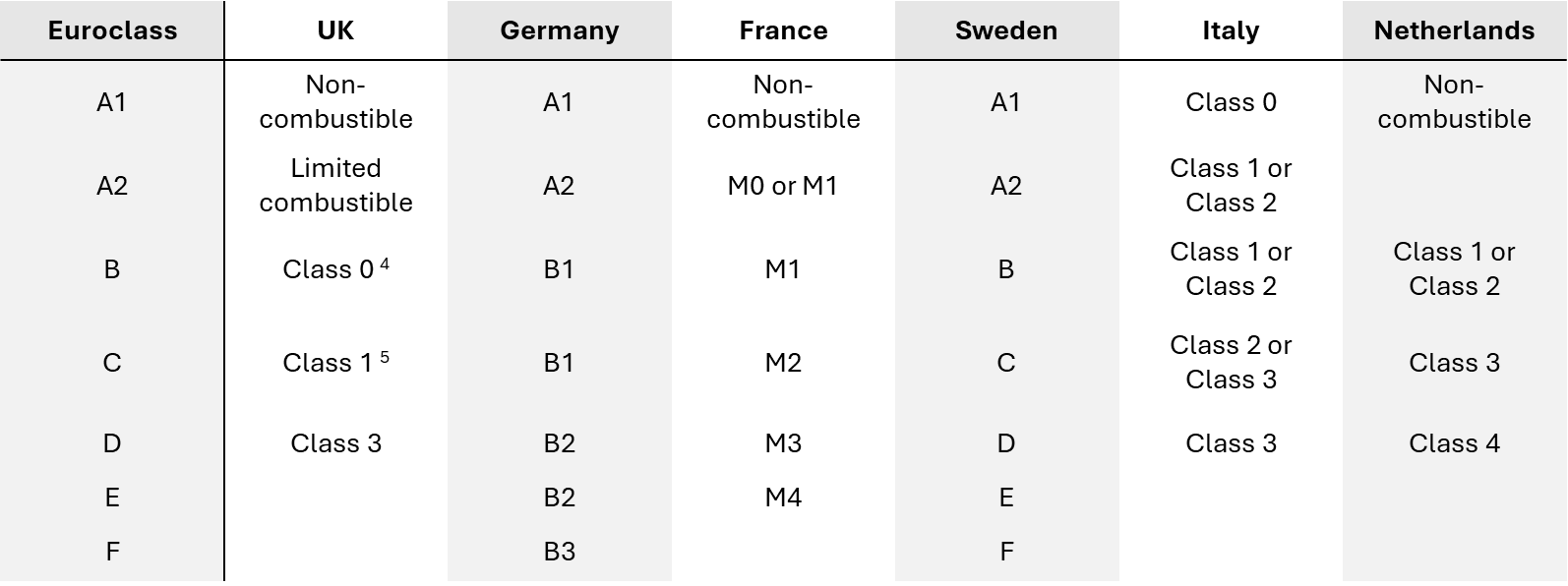

Equivalence Between European's Standard

Technical Datasheet

| Properties | Standard | Units | Standard | Description |

| Light transmittance | ASTM D 1003 | % | 85 | Visible light rate transmitted through the material. |

| Shore A hardness | EN ISO 868 | Sh A | 80 | Index based on a flat indenter's penetration depth. Scale from 0 (Soft) to 100 (Hard). |

| Tearing resistance | DIN 53515 | N/mm | 65 | Minimum tensile stress required to tear a pre-slit sample. |

| Tensile strength at break | ASTM D 638 EN ISO 527 | N/mm² | 20 | Maximum tensile stress that a material can be subjected to before break. |

| Elongation at break | % | 280 | Elongation of the specimen at the break point under tensile stress. | |

| Residual elong. (after break) | % | 60 | Permanent elongation of the specimen measured after rupture in a tensile test. | |

| Thermal conductivity | ASTM C 177 | W/m.K | 0,16 | Ability to conduct heat. The lower it is, the more insulation. |

| Cold bend brittle temp. | ISO 8570 | °C | -20 | Temperature at which the specimen break under torsion stress. Brittle point (CLASH & BERG). |

| Min. usage temp. | EN 1876 | °C | 0 | Temperature range where material keeps its mechanical properties (flexibility). |

| Max. usage temp. | °C | +50 | ||

| Specific heat capacity | ISO 11357 | kJ/kg.K | 1,6 | Heat energy required to increase the temperature of one kilogram of the material by one degree Celsius. |

| Sound reduction | DIN 52210 | dB | >35 | Average sound level (freq. 0,1 to 3,2 kHz) decreased by a 1,76 sq.m. and 5 mm thick PVC curtain. |

| Reaction to fire | EN 13501-1 | Class | C-s3,d0 B-s3, d0 | Standard classifications of material self-extinguishing and resistance to combustion. |

| UV/IR filter | ISO 25980 | - | - | Ability to filter welding rays allowing the use of this material as a welding protection screen. |

| UV resistance | ISO4892 | - | Yes | Ability to resist to UV (Sun, welding arc). |

| Surface resistivity | ASTM D257 | .1010 Ω/□ | 30 | Material surface electric resistivity measured with a 100 V direct voltage. |

| Water absorption | EN ISO 62 | % | -0,2 | Material mass variation after exposure to humid conditions. (<0 if released / >0 if absorbed) |

| Anti-insect | - | - | - | Special ability to keep insects away.(Food processing plants, tropical regions) |

| Density | ASTM D 792 | g/cm3 | 1,30 | Mass per unit volume. |

Free download

- FLEXIBLE VINYL - NON-PHTHALATE PLASTICIZER (EN).pdf

- FLEXIBLE VINYL - SOLUTION FOR BUILDING (EN).pdf

- FLEXIBLE VINYL - SOUND REDUCTION (EN).pdf

- FLEXIBLE VINYL - THICKNESS & THERMAL INSULATION (EN).pdf

- FLEXIBLE VINYL - THERMAL INSULATION (EN).pdf

- FLEXIBLE VINYL - STABILIZERS & DURABILITY (EN).pdf

- PLASTIC MATERIALS & EARTH’S ENERGY RESOURCES (EN).pdf

- PLASTIC MATERIALS & GLOBAL WARMING (EN).pdf

- PLASTIC MATERIALS & OIL RESSOURCES (EN).pdf