What are you looking for?

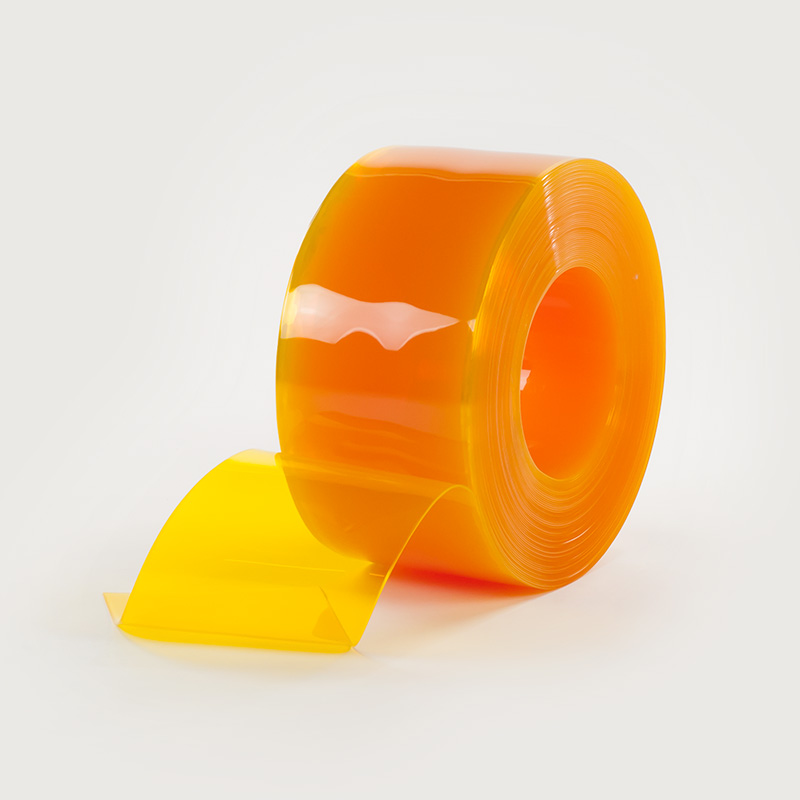

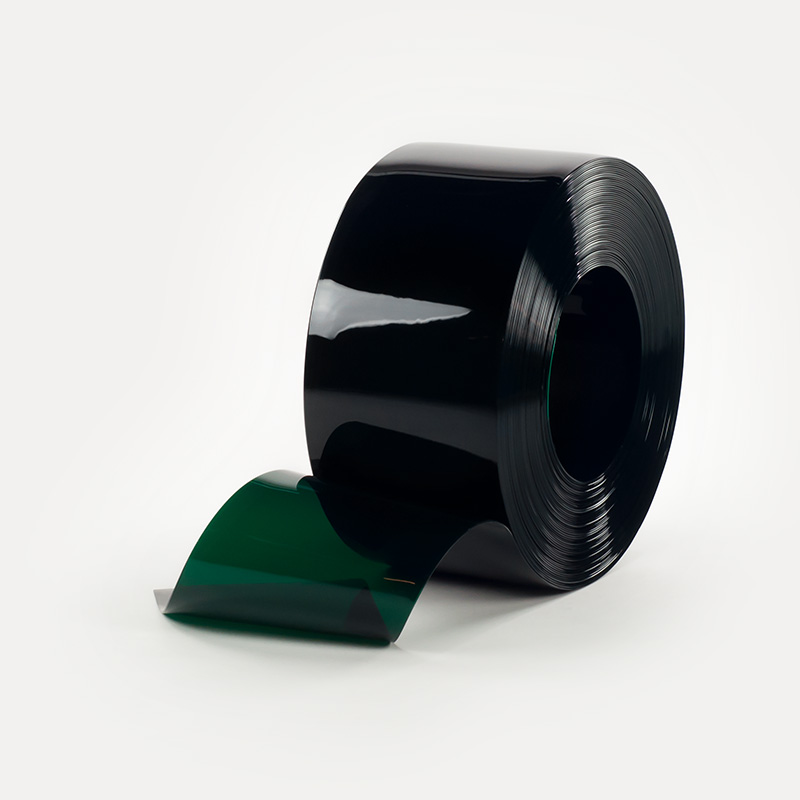

Transparent Coloured PVC

| Transparency/clarity |

| Thermal insulation |

| Noise insulation |

| Long durability |

| Impact & scratch resistance |

| Environment friendly & recyclable |

Formats

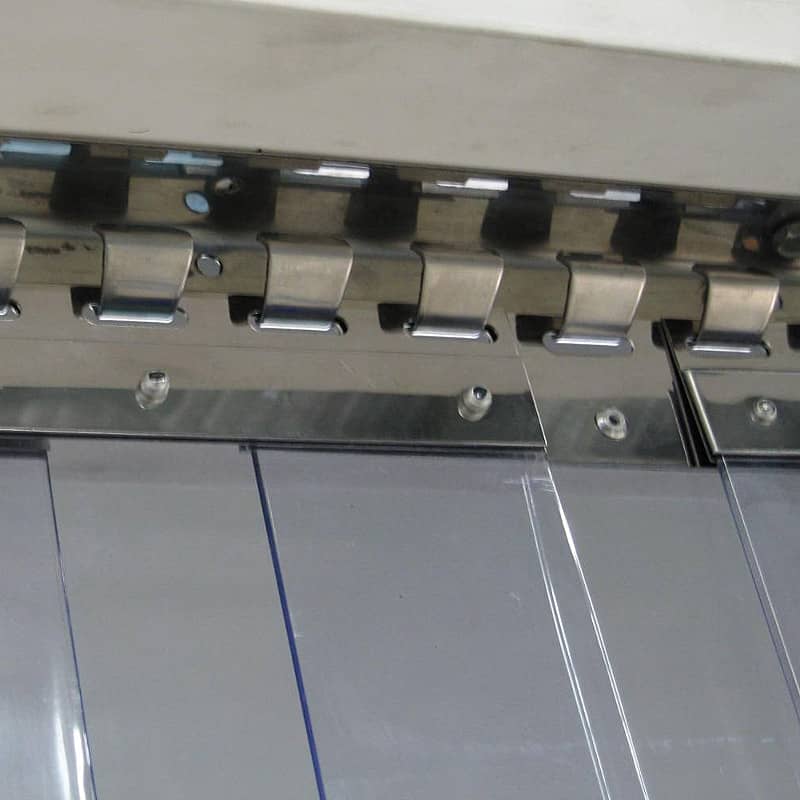

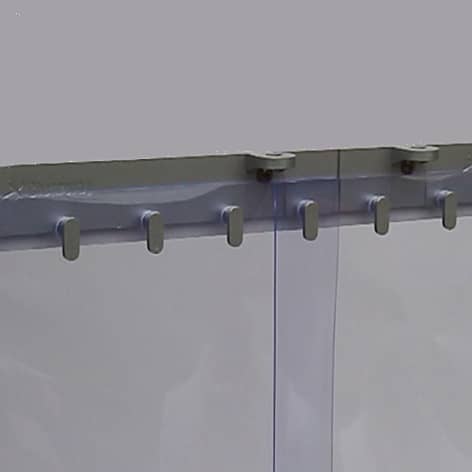

- Rolls, strips, curtains, panels and films

- Smooth, ribbed, reinforced, rounded edges, matt surface.

| Min | Max | |

| Width | 75 mm | 2.2 m |

| Thickness | 0.3 mm | 12 mm |

| Length | 20 m | 100 m |

About Coloured PVC

Extruflex's Transparent Coloured PVC range offers a wide variety of different colours on top of all the flexible vinyl qualities (clarity, brightness, durability, flexibility, and strong resistance to impact).

Transparent Coloured PVC is mainly recommended for safety signalisation, coloured and decorative strip doors, automatic doors, rapid doors or partitions in industrial and commercial buildings.

Applications

Why Use Transparent Colour PVC?

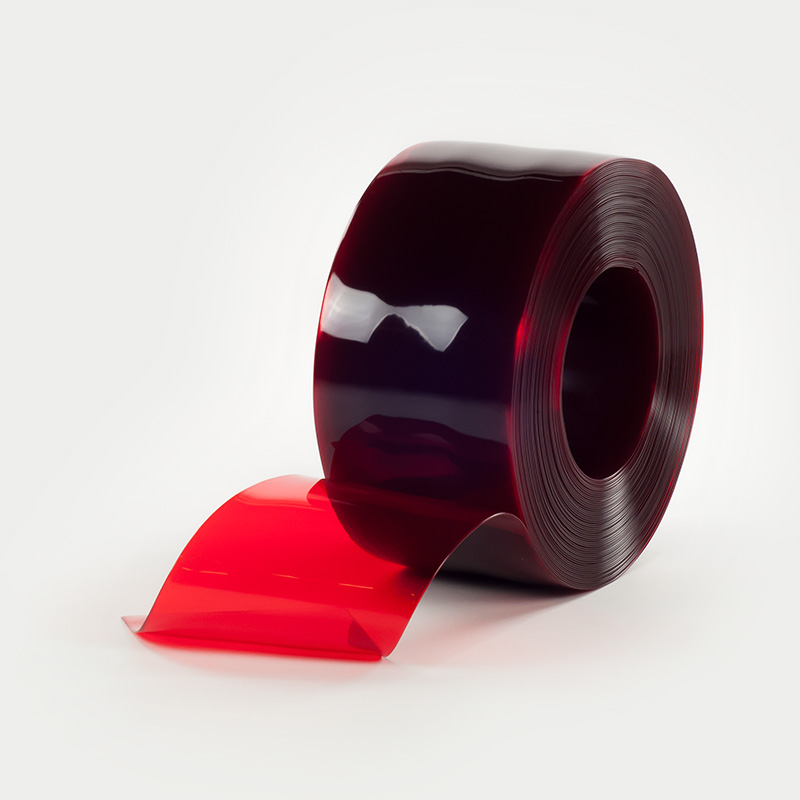

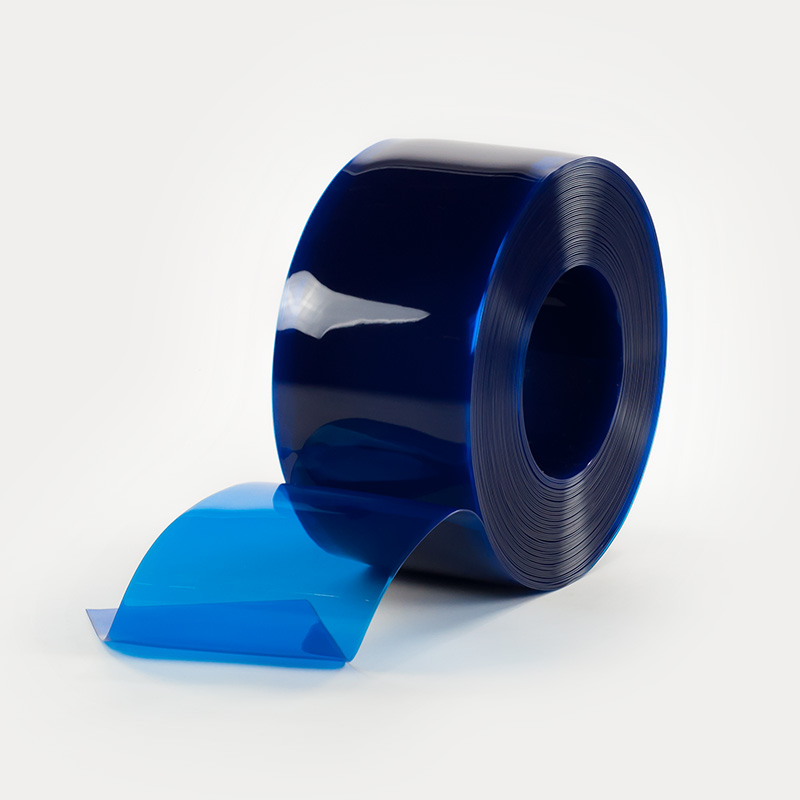

Extruflex's Transparent Colour PVC has a variety of different colours including red, blue, green, and orange.

Transparent Colour PVC can have a variety of uses, such as decoration for an event, or marketing and can also be used to demarcate certain areas or to be placed as safety markers at each end of a strip curtain.

This allows any traffic passing through the doorway to know where hazards or obstructions are.

Common Applications

- Partitioning

- Building insulation

- Commercial warehousing

- Flooring

- Safety markers

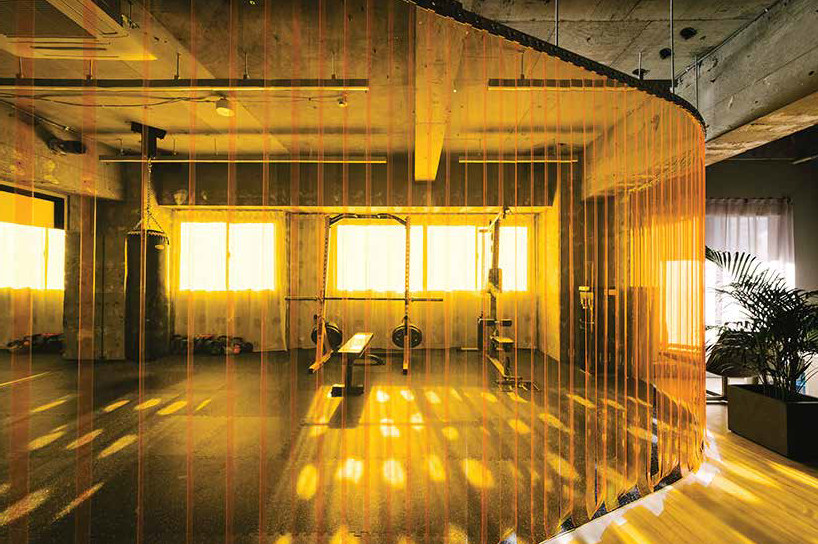

- Decoration & interior design

Bring Your Designs to Life With Colour

Flexible PVC has a huge variety of uses and benefits and coloured PVC has the additional great benefit of adding vibrant colours to your surroundings.

This highly decorative PVC comes in a variety of different colours and can add a unique look to your workplace or home. They can be turned into beautiful PVC strip curtains or doors to decorate offices, stores, workshops, gyms or restaurants. Their bright colours are eye-catching and able to grab the attention of possible customers or clients.

They can also be added to workspaces, to add some vibrant colours, to inspire creativity in employees.

Decorate With Light

Whether incorporating pristine colourful retail display areas, adding flair to a bar, or setting a particular mood in an office space, transparent-coloured PVC can help you achieve your goals.

Choosing the best colour to achieve this is up to you or your interior decorator.

Adding a particular hue to a room can change the entire look and feel of the room and therefore can change how people feel when entering the space.

Holds Other Great Benefits of Extruflex PVC

Flexible PVC has a variety of benefits and uses. It provides great insulation, keeping out the cold weather, and allowing you to save on your energy bills.

When used as strip curtains they also allow for fast-flowing pedestrian or light-vehicle traffic to pass through doorways easily and quickly, while still protecting the indoors from the external weather conditions.

All Extruflex PVC is the highest quality PVC available on the market, having the best durability, flexibility, and resistance to impact and chemicals.

All Extruflex PVC is also 100% recyclable and non-phthalate! This means that they are safer for you to use and better for the planet.

Health and Safety

Transparent Colour PVC is great for decorative purposes but is also extremely useful for other applications.

In addition to all the great benefits that come with flexible PVC, transparent-coloured PVC has the added benefit of having vibrant colours, allowing it to be used in a variety of different ways.

A common use is to put a strip of red transparent PVC at the ends of PVC strip curtains to warn personnel where the edges of the doorway are or to warn personnel that there are hazards beyond the strip curtains.

This is an important health and safety feature used at many factories and warehouses.

Another common use is to demarcate doorways with strip curtains of bright colours to clearly show that they are fire exits or escape routes in emergencies.

Technical datasheet

| Properties | Standard | Units | Standard | Description |

| Light transmittance | ASTM D 1003 | % | 0 to 80 | Visible light rate transmitted through the material. |

| Shore A hardness | EN ISO 868 | Sh A | 65 to 85 | Index based on a flat indenter's penetration depth. Scale from 0 (Soft) to 100 (Hard). |

| Tearing resistance | DIN 53515 | N/mm | 28 to 65 | Minimum tensile stress required to tear a pre-slit sample. |

| Tensile strength at break | ASTM D 638 EN ISO 527 | N/mm² | 12 to 20 | Maximum tensile stress that a material can be subjected to before break. |

| Elongation at break | % | 280 to 390 | Elongation of the specimen at the break point under tensile stress. | |

| Residual elong. (after break) | % | 60 to 76 | Permanent elongation of the specimen measured after rupture in a tensile test. | |

| Thermal conductivity | ASTM C 177 | W/m.K | 0,16 | Ability to conduct heat. The lower it is, the more insulation. |

| Cold bend brittle temp. | ISO 8570 | °C | -20 to -40 | Temperature at which the specimen break under torsion stress. Brittle point (CLASH & BERG). |

| Min. usage temp. | EN 1876 | °C | -15 to -25 | Temperature range where material keep its mechanical properties (flexibility). |

| Max. usage temp. | °C | +30 to +50 | ||

| Specific heat capacity | ISO 11357 | kJ/kg.K | 1,6 | Heat energy required to increase the temperature of one kilogram of the material by one degree Celsius. |

| Sound reduction | DIN 52210 | dB | >35 | Average sound level (freq. 0,1 to 3,2 kHz) decreased by a 1,76 sq.m. and 5 mm thick PVC curtain. |

| Reaction to fire | EN 13501-1 | Class | - | Standard classifications of material self-extinguishing and resistance to combustion. |

| UV/IR filter | ISO 25980 | - | - | Ability to filter welding rays allowing the use of this material as a welding protection screen. |

| UV resistance | ISO4892 | - | Yes | Ability to resist to UV (Sun, welding arc). |

| Surface resistivity | ASTM D257 | .1010 Ω/□ | 30 | Material surface electric resistivity measured with a 100 V direct voltage. |

| Water absorption | EN ISO 62 | % | -0,2 | Material mass variation after exposure to humid conditions. (<0 if released / >0 if absorbed) |

| Anti-insect | - | - | - | Special ability to keep insects away.(Food processing plants, tropical regions) |

| Density | ASTM D 792 | g/cm3 | 1,2 to 1,5 | Mass per unit volume. |

This information given to our customer in good faith to inform them and to help them in their search, does not constitute any formal or implicit guarantees as to its use.

Free download

- FLEXIBLE VINYL - NON-PHTHALATE PLASTICIZER (EN).pdf

- FLEXIBLE VINYL - SOLUTION FOR BUILDING (EN).pdf

- FLEXIBLE VINYL - SOUND REDUCTION (EN).pdf

- FLEXIBLE VINYL - THICKNESS & THERMAL INSULATION (EN).pdf

- FLEXIBLE VINYL - THERMAL INSULATION (EN).pdf

- FLEXIBLE VINYL - STABILIZERS & DURABILITY (EN).pdf

- PLASTIC MATERIALS & EARTH’S ENERGY RESOURCES (EN).pdf

- PLASTIC MATERIALS & GLOBAL WARMING (EN).pdf

- PLASTIC MATERIALS & OIL RESSOURCES (EN).pdf